Installing Cor-Ten Steel Edging in the Garden: Complete Step-by-Step Plan

Cor-Ten steel has become very popular among garden enthusiasts in recent years. This unique material combines durability with a beautiful rust-brown patina. That’s why many people choose it for various garden products. In this blog, we will delve into the indispensable Cor-Ten steel edging. Want to install Cor-Ten steel edging and looking for tips and inspiration? Read on quickly!

Summary

- Ensure that at least 5 centimeters of a 15-centimeter high edging is embedded in the ground. We will explain step by step how to correctly install an edging.

- Cor-Ten steel is more durable than steel, plastic, and wood. Stone lasts longer, but is less flexible than Cor-Ten steel.

- An edging can be bent independently up to 3 millimeters. For thicknesses above 3 millimeters, specialized tools are required.

- Cor-Ten steel requires almost no maintenance, but can be cleaned with a mild all-purpose cleaner and water.

- Do not use sharp objects when maintaining the garden around the edging.

What to Consider When Installing Cor-Ten Steel Edging?

When placing Cor-Ten steel edging in your garden, it's important that the soil is firm and slightly moist. This prevents the edging from sinking. Choose sturdy anchors (our small and large Cor-Ten steel ground pins) and coupling plates (our small and large Cor-Ten steel coupling plates) that fit well with the edging.

MySteel offers complete sets (for example, for an edging of 24 meters long) that include the edging and all other materials you need.

Make sure to prepare the soil properly and attach the edging correctly for the best results. Below we explain step by step how you can do this.

Preparing the Soil

- Remove weeds and level the ground.

- Place stakes to indicate the area.

- Start at the highest point and place a string between the stakes as a reference point.

- Spread the soil evenly with a rake at the same height.

- Check the heights carefully and compact the soil firmly.

- Let the soil rest and water regularly to prevent drying out.

- Then mark the boundaries where the edging should be placed.

How High Should the Edging Be?

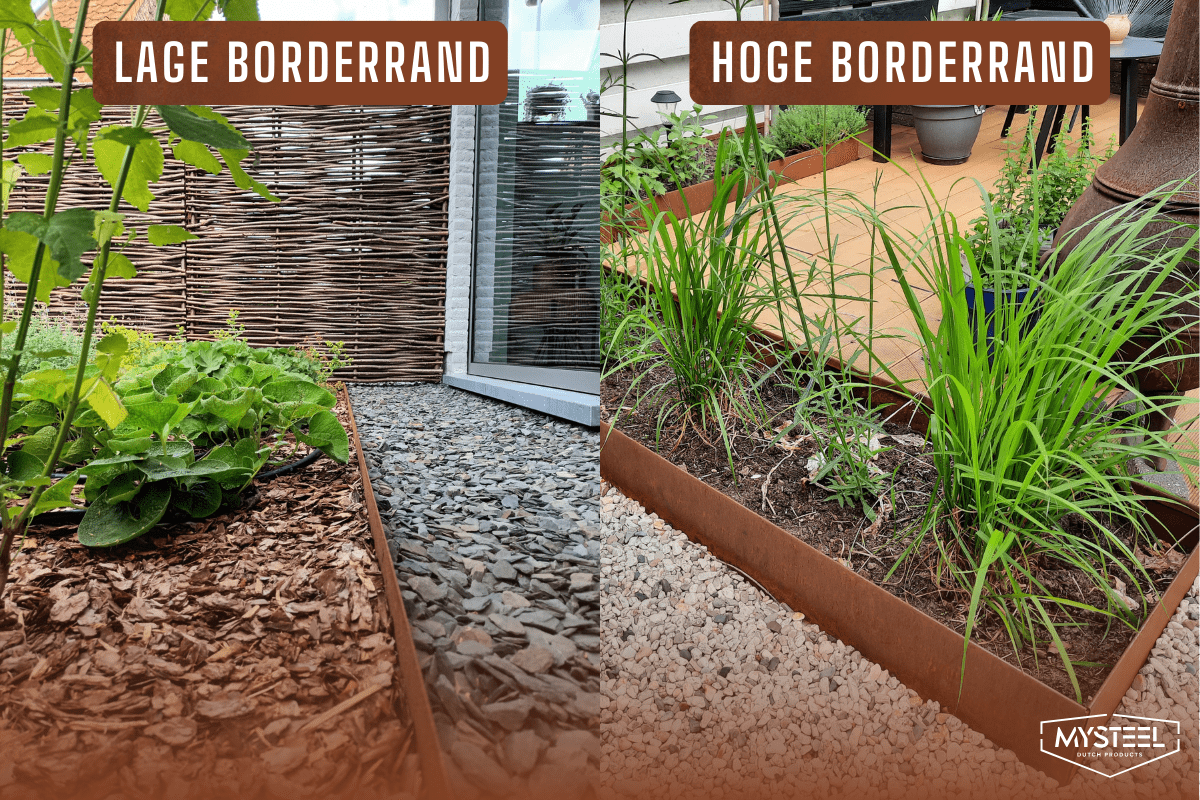

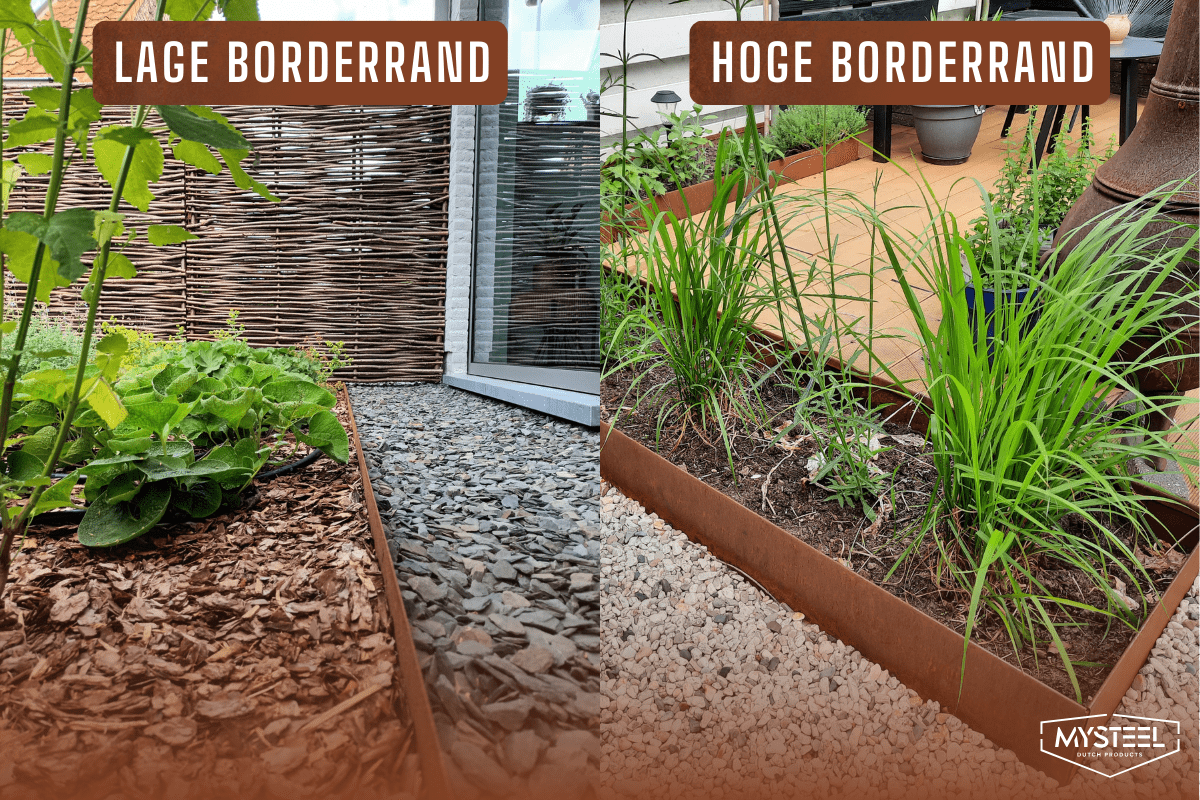

The correct height of an edging depends on what you intend to do with it.

Plant Choice and Slopes

For flower beds, a higher edging is necessary for taller plants, such as bamboo or delphinium, to keep them in place. For shorter plants, a lower edging is better.

On gentle slopes, a Cor-Ten steel edging of 22 centimeters or higher is a good option to hold back soil.

For steeper slopes, it's better to have a 40-centimeter edging (for example, a Cor-Ten steel retaining wall).

Look and Feel

The desired appearance of the garden also plays a role. If you want a natural look, choose lower edges. But if you want a sturdier and tougher garden, it's best to use higher edges.

Reading Tip

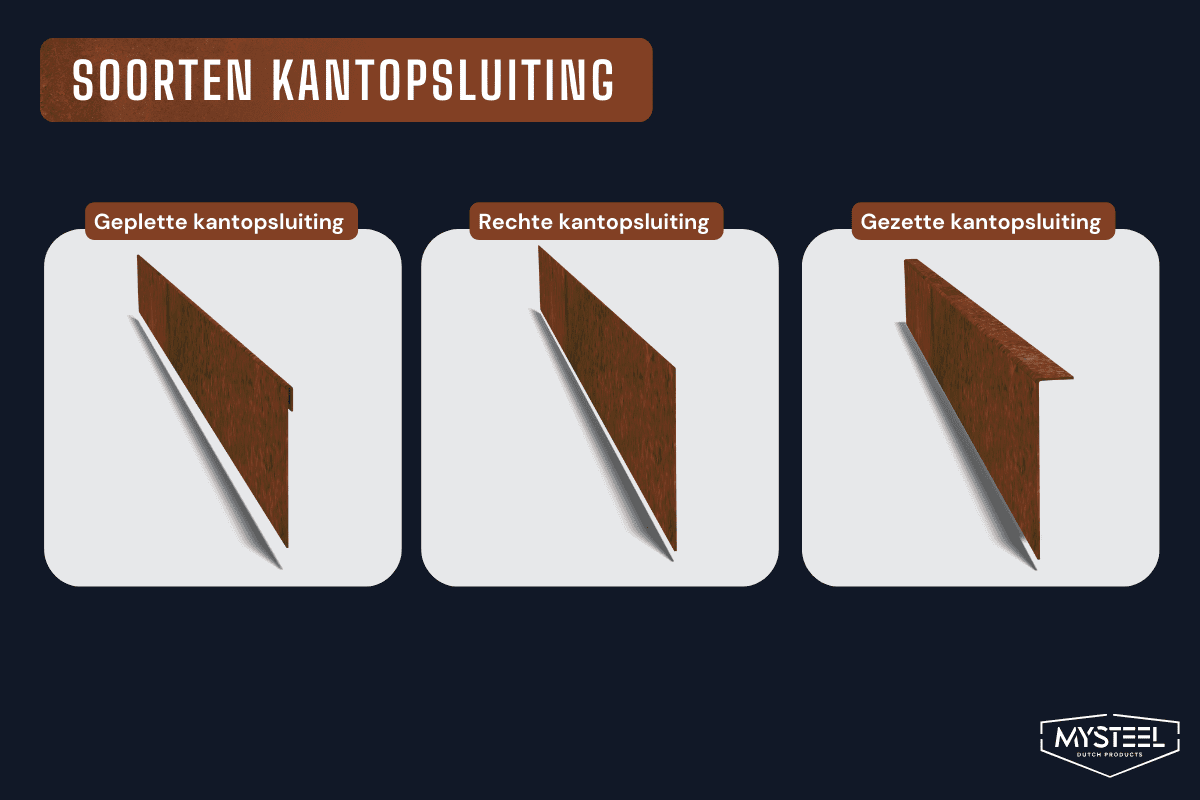

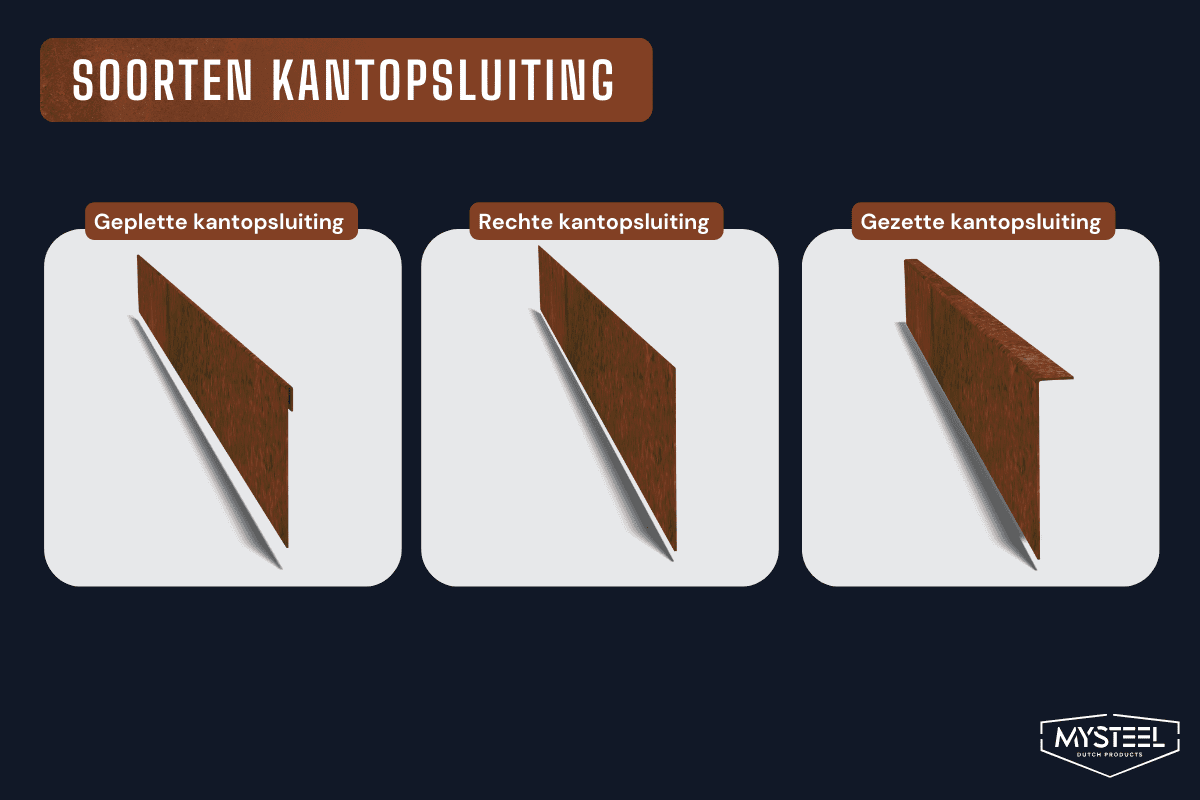

The edging is available in 3 shapes. Read more about this in our blog on the different types of edging.

Safety

Keep in mind that edgings with a certain height can be dangerous for children or pets. Especially when the edging is around a garden path, there is a higher chance of tripping. The flattened edging is the most child- and pet-friendly: the edge is rounded, making it less sharp.

Maintenance

The higher the edging, the more dirt can accumulate along the edge. This also means that you will need to clean the higher edge more often to keep it looking neat. Read more about this in the paragraph "maintenance and protection".

“When determining the height of the edging, consider safety, aesthetics, maintenance requirements, and your plant choices.”

Dirk – Product Specialist

How Deep Should the Edging Be Placed in the Ground?

We generally recommend placing the edging at a depth of about one third to half the height of the edging into the ground. This keeps the edging stable and prevents it from sinking. For example, if your edging is 15 centimeters high, it is best to set it about 5 to 7.5 centimeters deep into the ground.

Securing the Edging

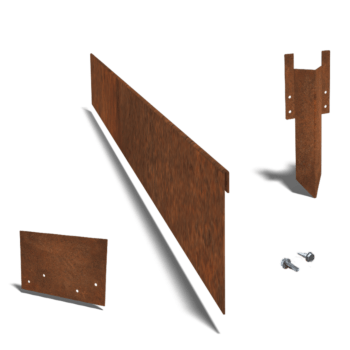

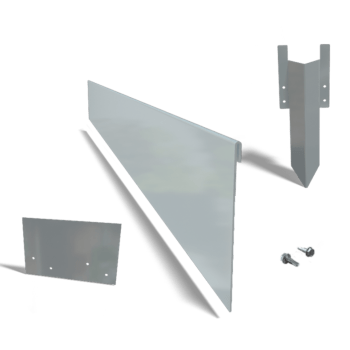

So how do you actually install a Cor-Ten steel edging? In the MySteel webshop, you can choose from Cor-Ten steel edgings, Cor-Ten steel retaining walls, and Cor-Ten steel U-profiles.

Here’s how to install a straight edging:

- Gather all the necessary materials: edging, ground pins, coupling plates, and self-tappers. If you order a complete edging set from MySteel, you will receive all the other materials you need along with the edging. If you only buy the edging, you will need to order the other materials separately.

- Cut the edging to size: The MySteel edgings are available in standard lengths of 1.5 meters or 2.4 meters. Don’t worry if they don’t fit precisely, as you can easily cut them to size with a grinder.

- Attach ground pins and coupling plates: Before firmly securing your edging into the ground, it’s important to mount the ground pins and coupling plates. Secure them against the edging with self-tappers for extra stability. Use a drill with an 8-millimeter bit for this task.

- Place the Cor-Ten steel edging: Now it’s time for the fun part. Mark the boundaries of your garden edging by digging a trench. Then set the edging into the ground by tapping the protruding part of the ground pin with a hammer. We recommend placing the edging at least 5 centimeters deep into the ground. This way, the self-tappers will be completely below ground and not visible.

Difference with Other Edging Materials

When choosing edging for your garden, you need to consider what material you want to use. You have various options. Each type of material has unique properties.

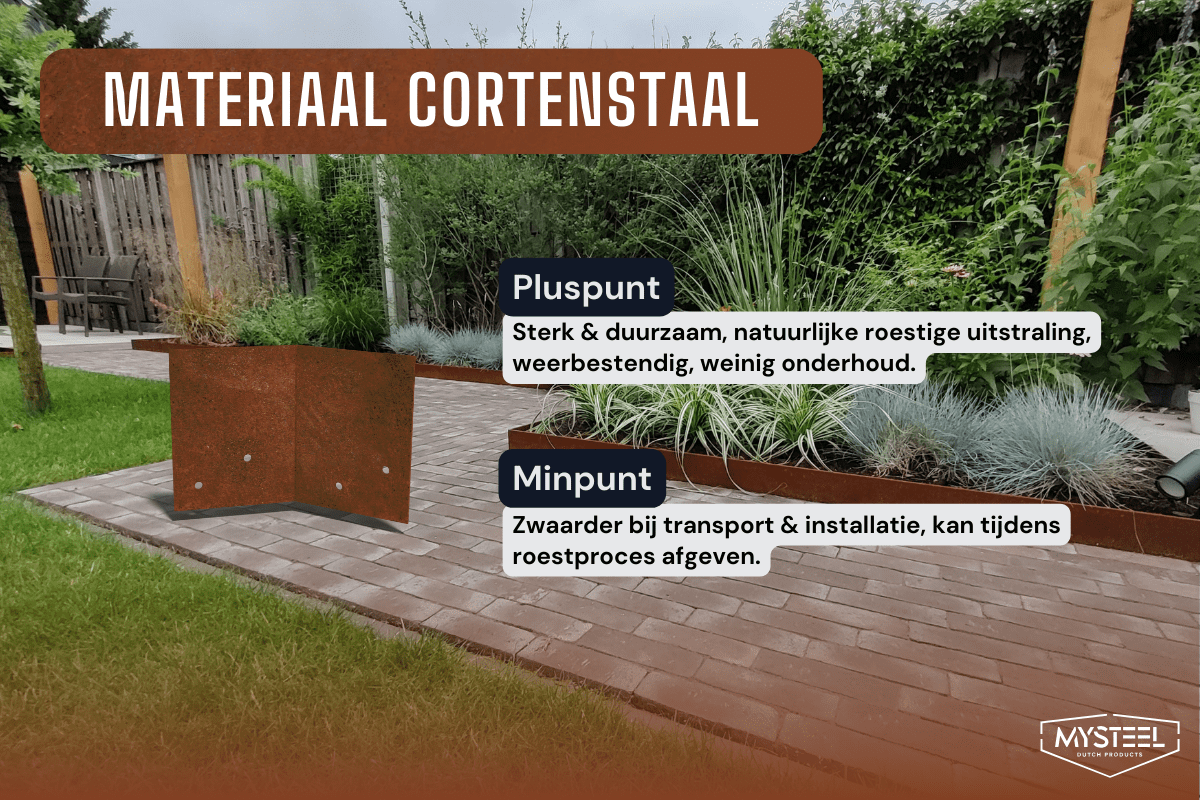

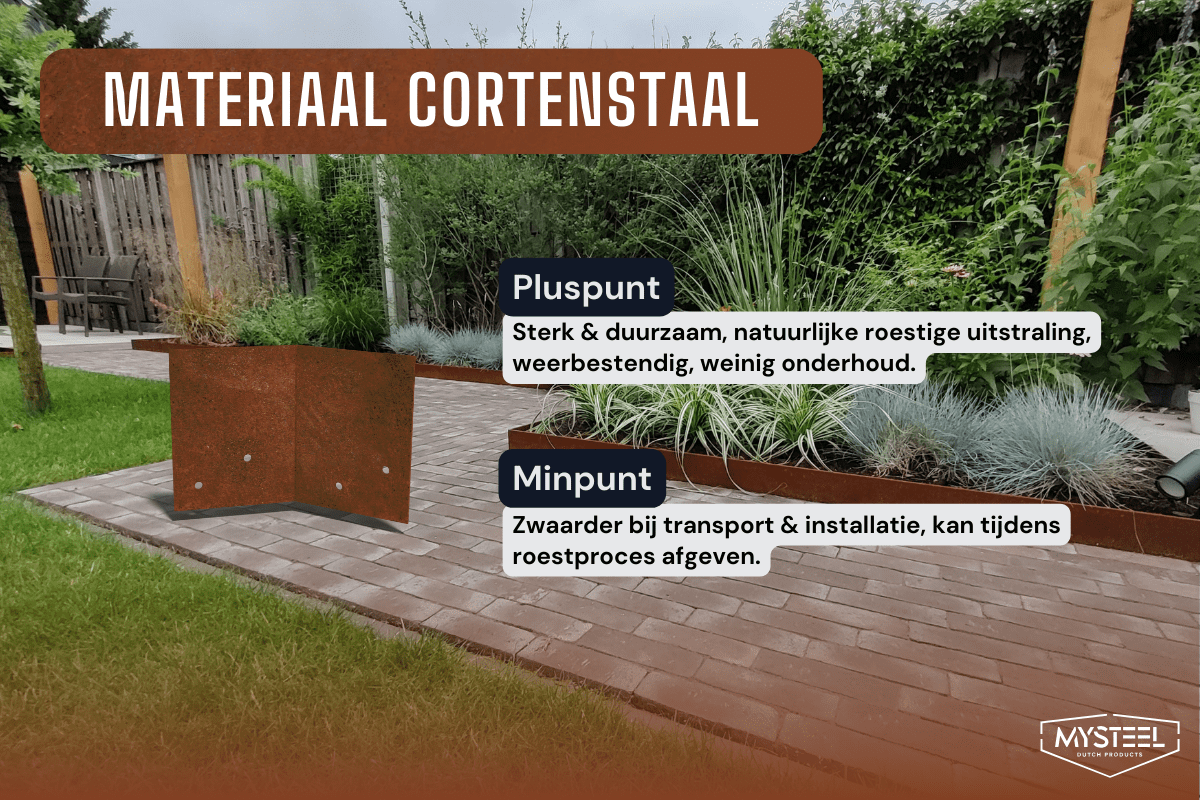

Steel and Cor-Ten steel are strong and last a long time, but the rust aspect and maintenance differ. Plastic is lightweight and flexible, while wood has a natural appearance but is prone to rot. Stone is durable, but Cor-Ten steel has a modern look and more flexibility.

To make your choice easier, we have compared each material with Cor-Ten steel below. We provide the pros and cons for each material.

Steel vs. Cor-Ten Steel

Steel

| Pros | Strong, durable, smooth surface. |

| Cons | Sensitive to rust, requires regular maintenance to prevent corrosion. |

Cor-Ten Steel

|

Pros |

Strong and durable (more than steel), natural rusty appearance, weather-resistant, low maintenance. |

| Cons | Often higher costs, rust color may transfer during rusting process. |

Plastic vs. Cor-Ten Steel

Plastic

| Pros | Light for transport and installation, weather-resistant, low maintenance, flexible and can be molded into various shapes, available in different colors. |

| Cons | Less natural appearance, color can fade from sunlight, less strong. |

Cor-Ten Steel

| Pros | Natural and warm appearance, more durable than plastic, rust-resistant, virtually unbreakable. |

| Cons | Heavier for transport and installation, may transfer rust during the rusting process, often higher costs. |

Wood vs. Cor-Ten Steel

Wood

| Pros | Natural look, lightweight, and easy to work with/install. |

| Cons | Prone to rot and insects, limited lifespan, requires regular maintenance. |

Cor-Ten Steel

| Pros | Durable and weather-resistant, long lifespan with minimal maintenance requirements. |

| Cons | Often higher costs, less flexible compared to wood in terms of shape change. |

Stone/Concrete vs. Cor-Ten Steel

Stone

| Pros | Durable, natural appearance, low maintenance, available in various colors and textures. |

| Cons | Heavy, not flexible, less possibilities in shape. |

Cor-Ten Steel

| Pros | Modern look, more flexible in shape. |

| Cons | Slightly less durable than stone. |

How Can I Best Bend the Edging to the Shape of My Garden?

The thickness of Cor-Ten steel affects the bending process. Thin sheets of 1 to 2 millimeters of edging are more flexible than sheets that are 3 millimeters or thicker. Generally, you can easily bend Cor-Ten steel up to about 3 millimeters. Thicker sheets may require specialized equipment.

MySteel offers a customization service where you can order plates that are thicker than 3 millimeters. They can then be bent precisely according to your specifications. Customization is offered above 50 running meters for edgings and overlay profiles. Customization is available earlier for retaining walls.

What Type of Edging Should I Use?

Edging comes in different forms: flattened, straight, and set. Each form is suitable for different purposes:

- Flattened edging is good for straight lines and gentle slopes.

- Straight edging is good for straight lines, curves, and circles.

- Set edging is good for straight lines in the garden.

- Flattened Flex edging is good for straight lines, gentle slopes, and is easy to install.

What is the minimum circle that you can make with a straight edging?

This strongly depends on which edging variant you use. The smallest circle you can create is a circle with a diameter of 1.6 meters. With the 1.5-meter length variant, the minimum circle diameter is 4.8 meters. If you use the 2.4-meter long edging, a circle diameter of 3.2 meters is possible.

Bending Cor-Ten Steel Edging: Step by Step

For bending an edging, it’s best to use a straight edging.

Bend the straight edging as follows:

- Measure where you want the bend to be precisely.

- Lay the edging on a raised surface.

- Place your knee on the spot where the edging should be bent. Use your hand to gently bend the other side of the edging downwards.

- Turn the edging over and place a thick board against the bend. Then bend the edging further against the board until you reach the desired angle.

To bend the flattened edging, you need to slightly grind the edge. This prevents the flattened edge from folding unattractively. The set edging cannot be bent at all. For this, use the corners and bends of the set edging.

What if the Edging is Thicker than 3 Millimeters?

Round and Corner

If the edging is thicker than 3 millimeters, you will need special tools, such as a grinding machine and a rolling machine. Specialized knowledge is also required to get it into the correct shape.

Maintenance and Protection

To maintain and protect a Cor-Ten steel edging, it's best to clean the surface with a mild all-purpose cleaner and water. Avoid using harsh cleaning agents such as bleach and abrasive cleaners, as well as salt. This helps preserve durability.

Mowing Grass

If you have a Cor-Ten steel edging around your lawn, there is a chance that the mower will cause damage. To prevent this, we have some simple tips to help protect the edging and ensure it stays beautiful for many years.

- Before you start mowing, it’s important to clear the grass from stones or other debris. Small objects can easily hit the edging and cause dents or damage.

- Use a grass trimmer with plastic blades or strings when mowing close to the edging. These will not damage the edging.

- With a grass shear, you can trim around the edging accurately.

What if Scratches Occur?

No need to panic! If scratches occur on a Cor-Ten steel edging, the damaged area will rust again and eventually develop a uniform rusty appearance, just like the rest of the material.

Read more about maintenance in our blog on Cor-Ten steel maintenance.

Pruning Plants

When it’s time to prune the plants around your Cor-Ten steel edging, it’s important to work neatly. This protects both the plants and the edging itself.

- Use manual pruning shears instead of electric ones for more control.

- Avoid contact with sharp objects and temporarily cover the edging with protective material, such as a cloth. This minimizes the chance of damage to both the plants and the edging. It also makes your working environment safer.

Removing Weeds

With the following tips, you will discover how to easily remove weeds around your Cor-Ten steel edging:

- Do not use chemical weed killers. Due to their corrosive properties, they can be harmful to Cor-Ten steel edgings.

- Consider using ground cover such as mulch or gravel around the edging. This can help to reduce weed growth and make removal easier.

- Remove weeds manually with a weed puller and gardening gloves.

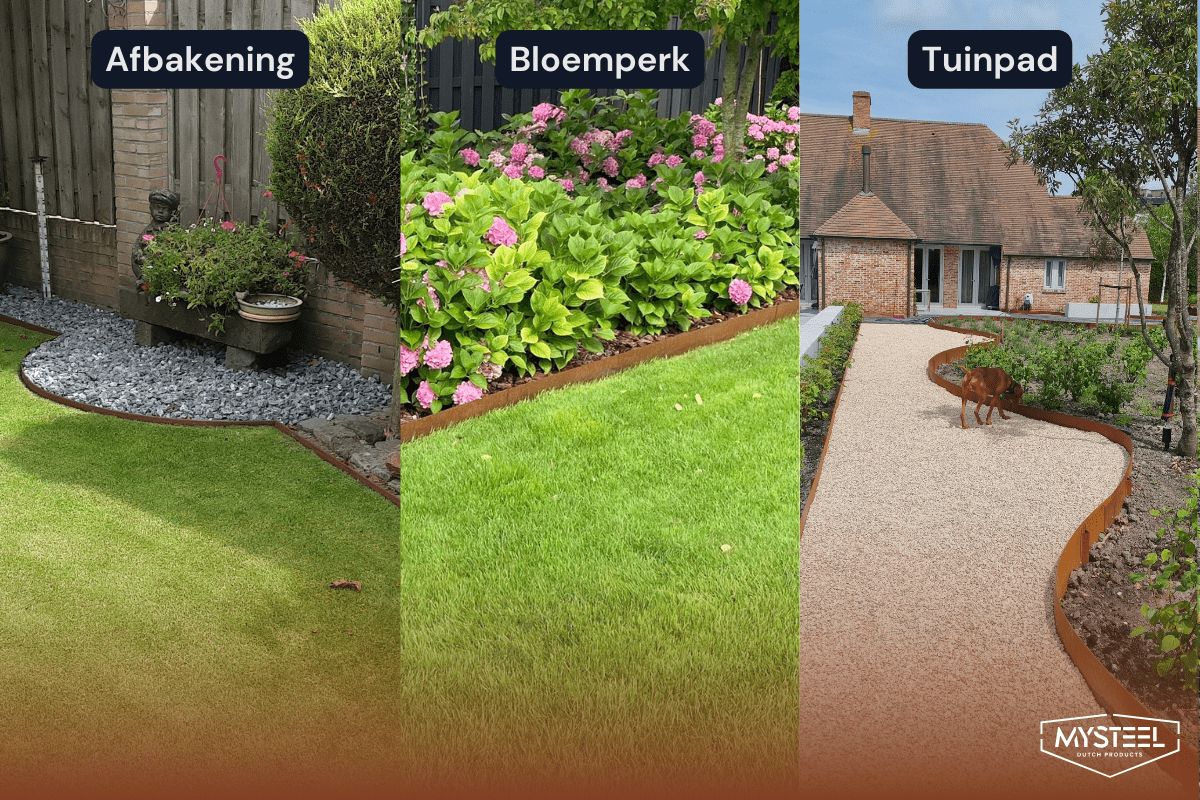

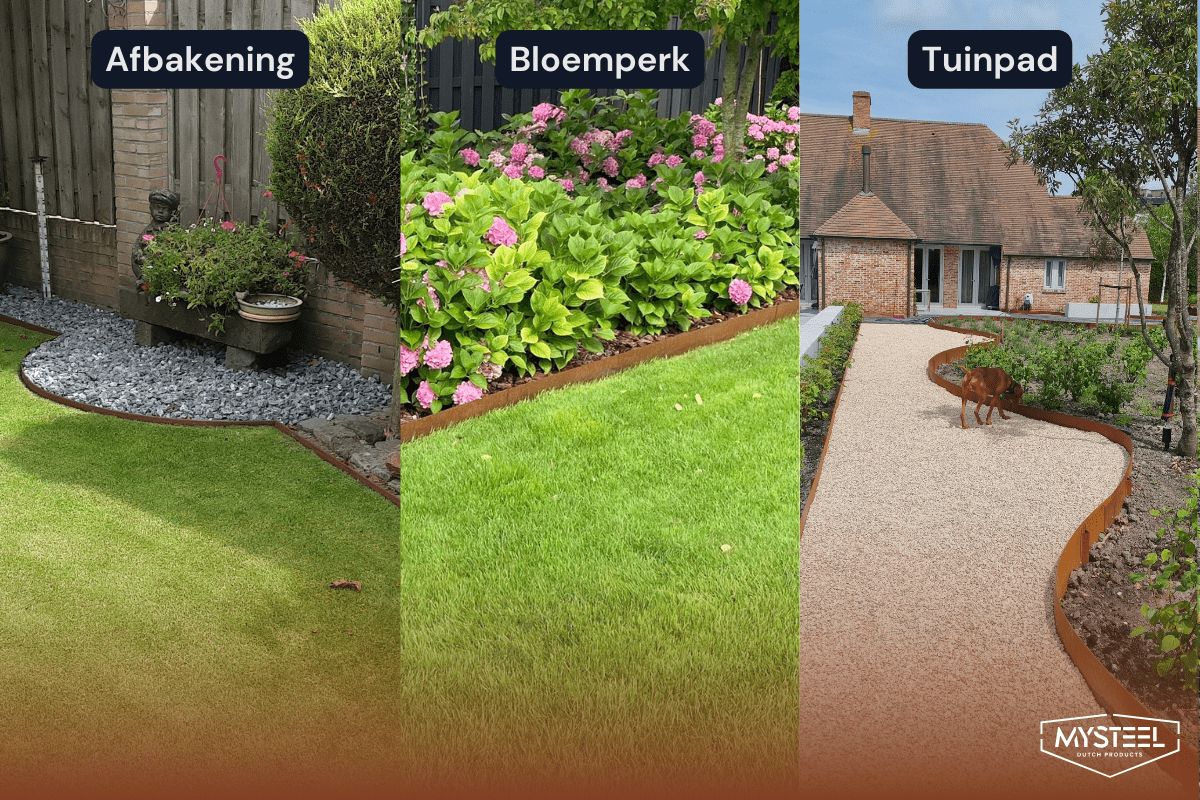

Practical Applications and Inspiration

Cor-Ten steel edgings serve as charming demarcations in gardens, flower beds, and paths. Whether you choose for clean lines or organic shapes, Cor-Ten steel offers endless possibilities for the appearance of your garden. The rust layer adds warmth to the landscape, while the durable character and weather resistance ensure long-lasting enjoyment. Get inspired by these beautiful creations:

Conclusion

You now know precisely how to carefully install Cor-Ten steel edgings. Take on the challenge and beautify your garden with Cor-Ten steel edgings. This way, you can truly turn your garden into a beautiful green oasis!