Welding corten steel: how do you do that?

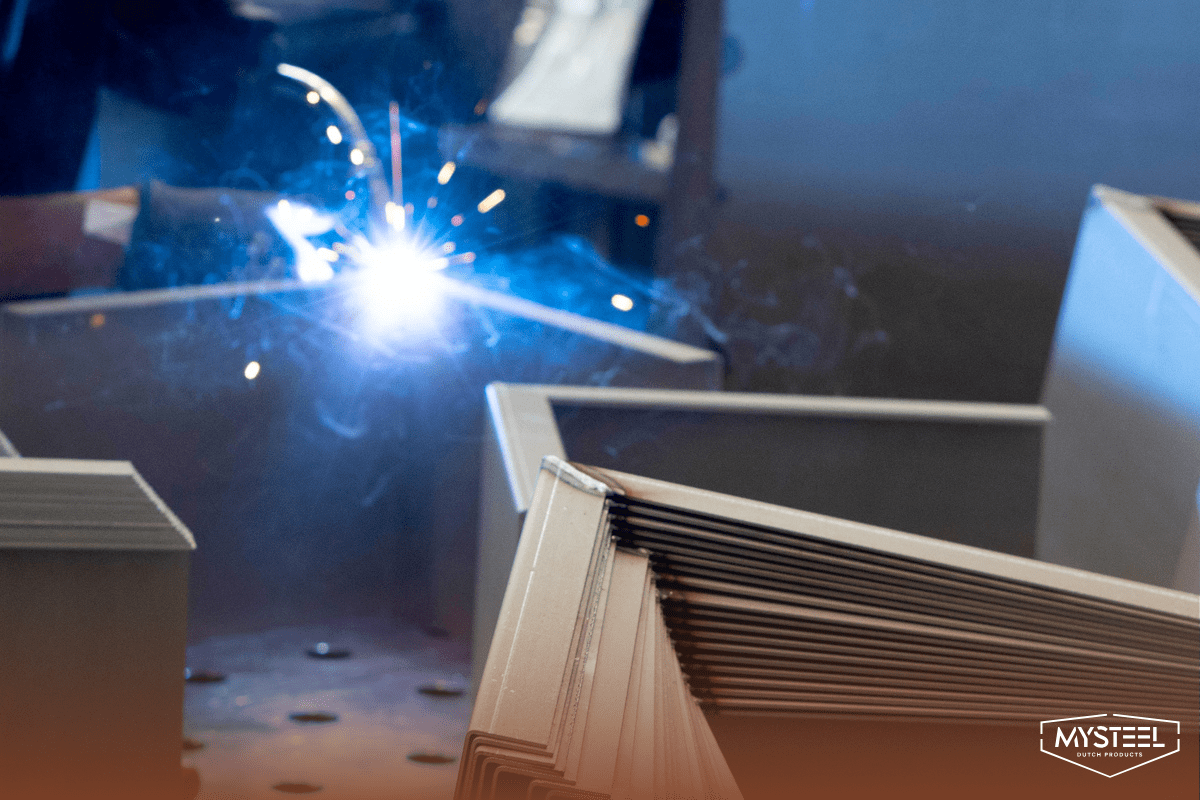

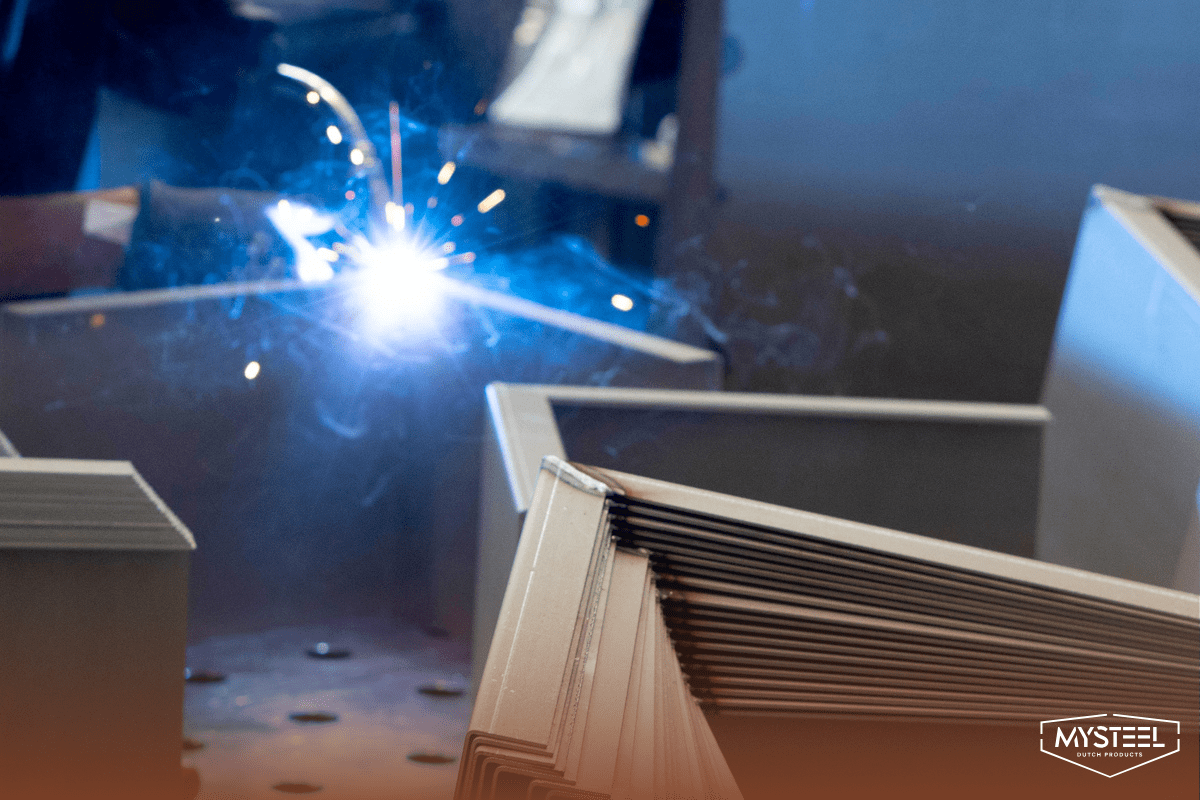

A good way to design beautiful garden products with corten steel is by welding it. This allows you to create sturdy structures without affecting the brown-orange color.

To achieve a nice and durable result, you must carry out the process correctly and neatly. The weld must be strong, especially if you want to smooth it later. Therefore, it is important to properly set the welding machine so that the material melts sufficiently.

Although people often think that welding corten steel is a challenge, the process is not very different from welding other metals. Want to know how it works exactly? In this blog, we provide you with a detailed step-by-step plan for welding corten steel. This way, you can get started soon!

Note

Keep in mind that the warranty of MySteel products expires if you weld them yourself.

Summary

- The welding process of corten steel is not much different from that of other metals.

- You can weld corten steel in various ways: electrode, MIG/MAG, and TIG.

- To achieve a nice and durable result, you must use the right welding wires and materials.

- After welding corten steel, it is important to properly finish and protect the product.

What should you pay attention to when welding corten steel?

Corten steel may seem complicated to many people at first, but that's actually not the case. You don't need to take special precautions when working with corten steel.

Corten steel has a special alloy that prevents the material from rusting through, but this does not affect the welding process itself. Just like with regular steel, you don't have to worry about protection against corrosion when welding corten steel. Heat management is always important because too much heat can cause the material to warp.

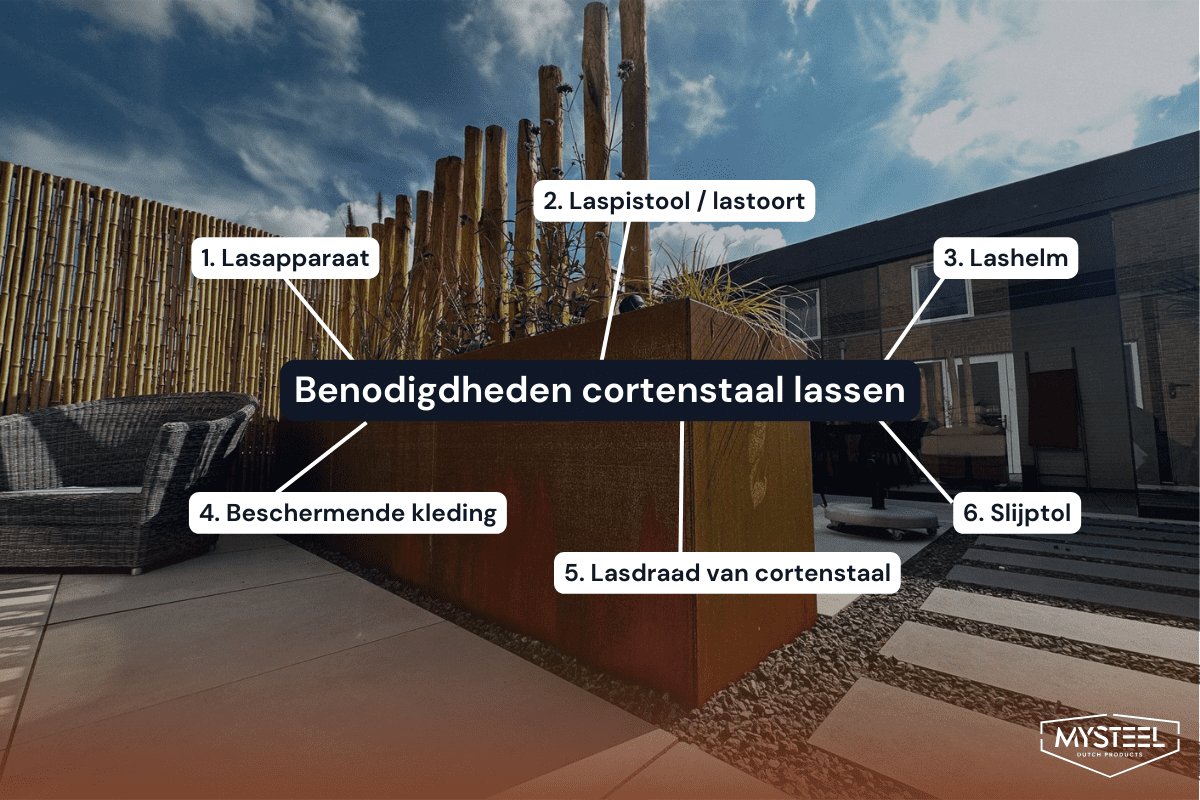

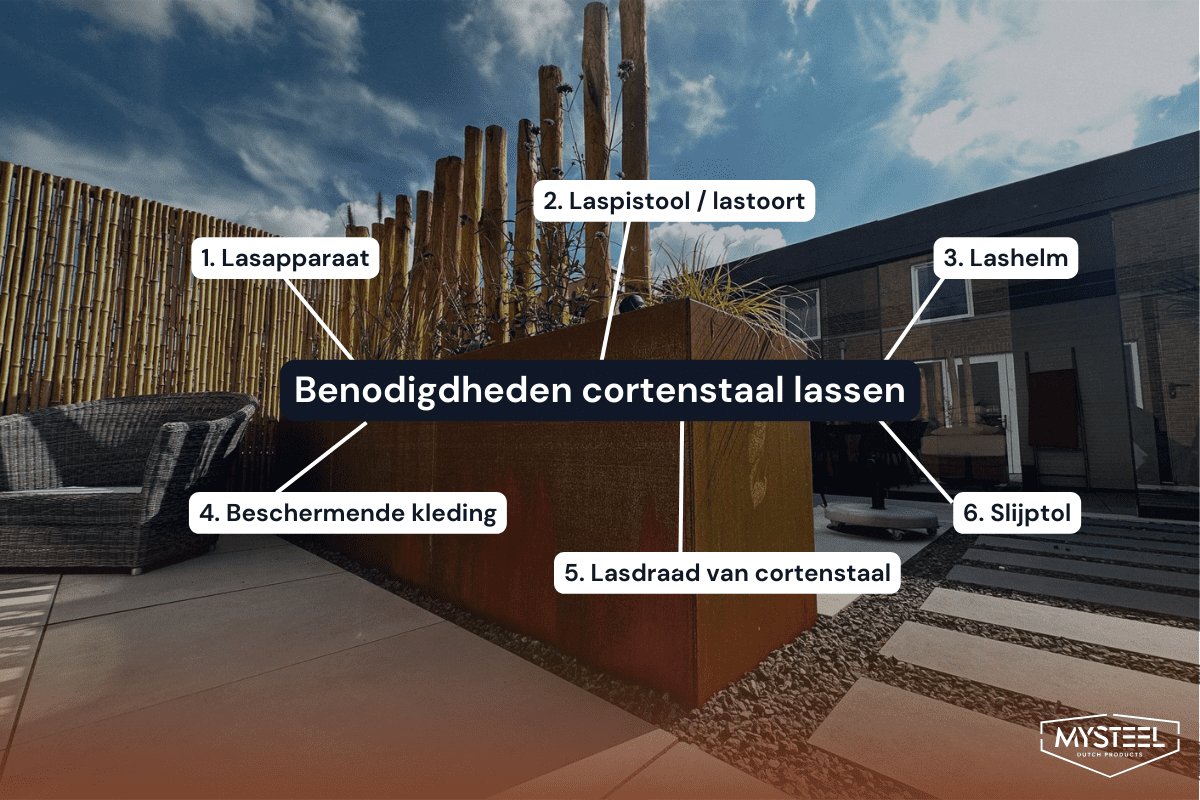

What do you need to weld corten steel?

To weld corten steel, you need various tools and materials:

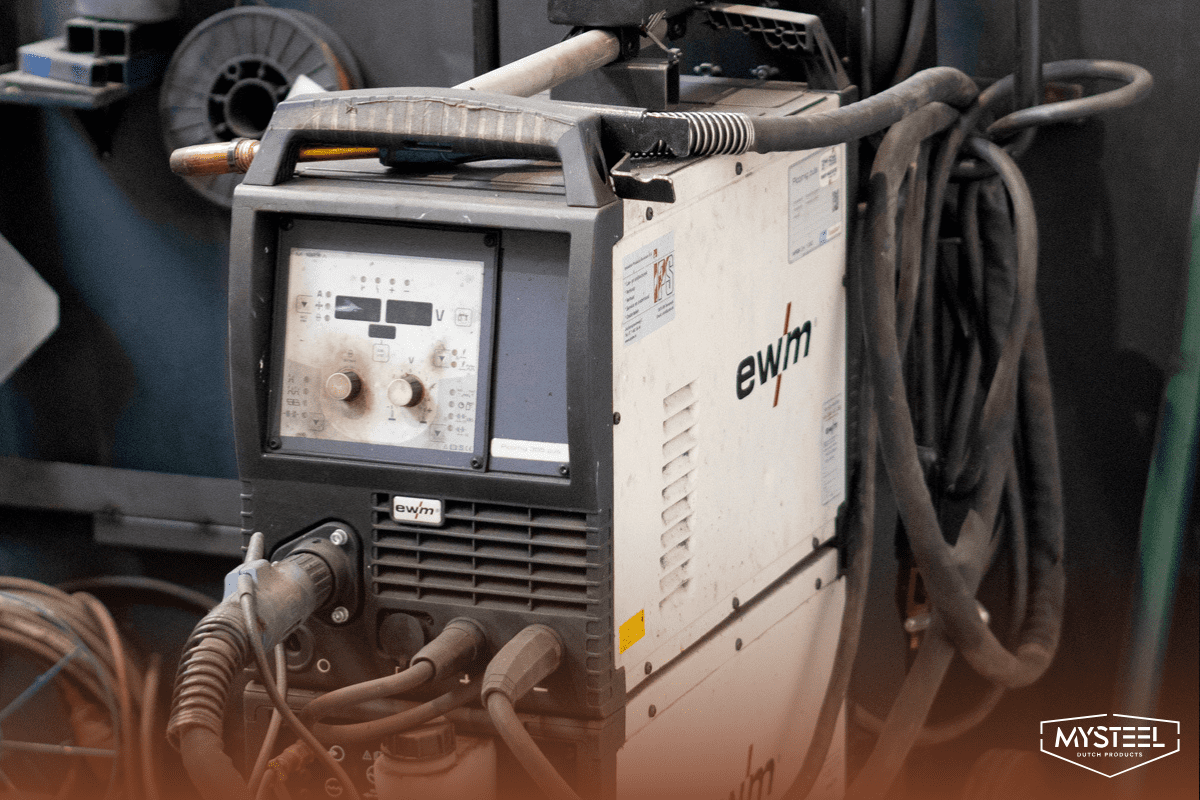

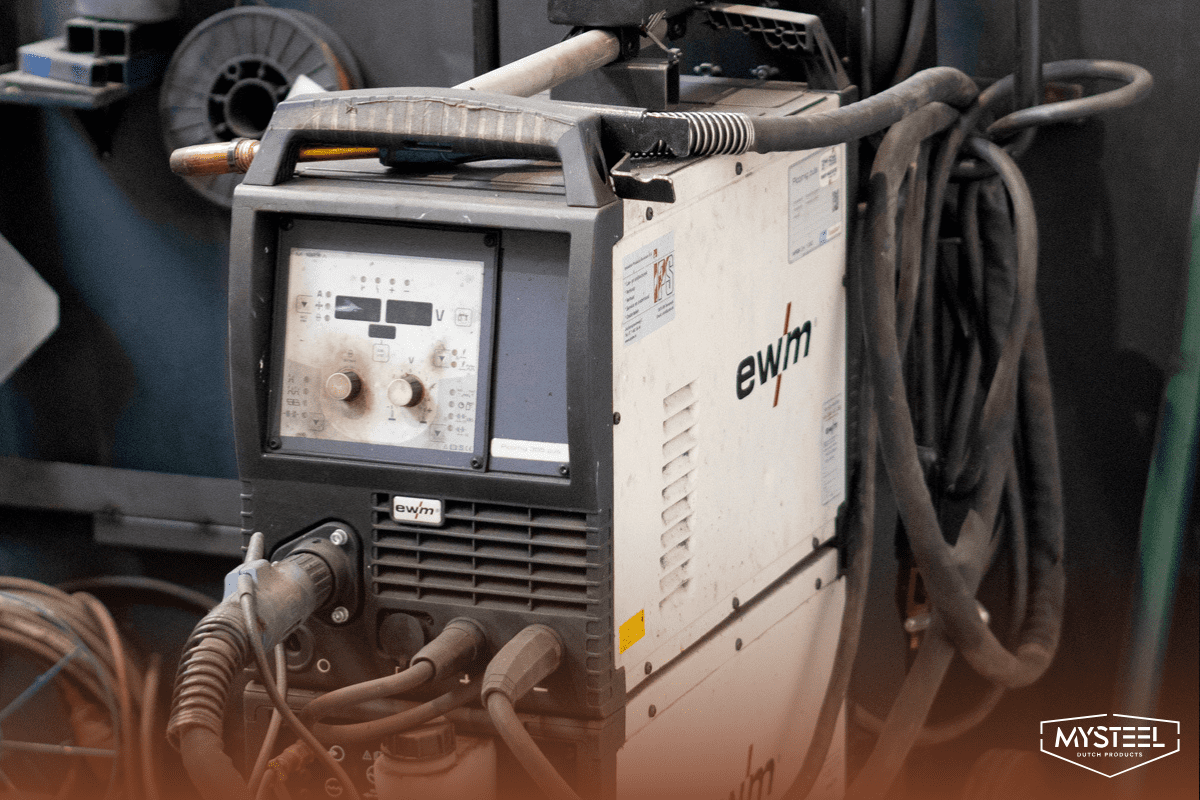

- A good welding machine: You have various options, such as CO2 welding machines, electrode welding machines, and TIG welding machines.

- A welding gun or torch: To join the metal parts together with intense heat.

- A welding helmet: To protect your face from flying sparks and bright light. This enhances safety and comfort while working.

- Protective clothing such as an overall and heat-resistant gloves: To protect your body from sparks and heat. This clothing must meet the EN-ISO 11611 standard to provide adequate protection.

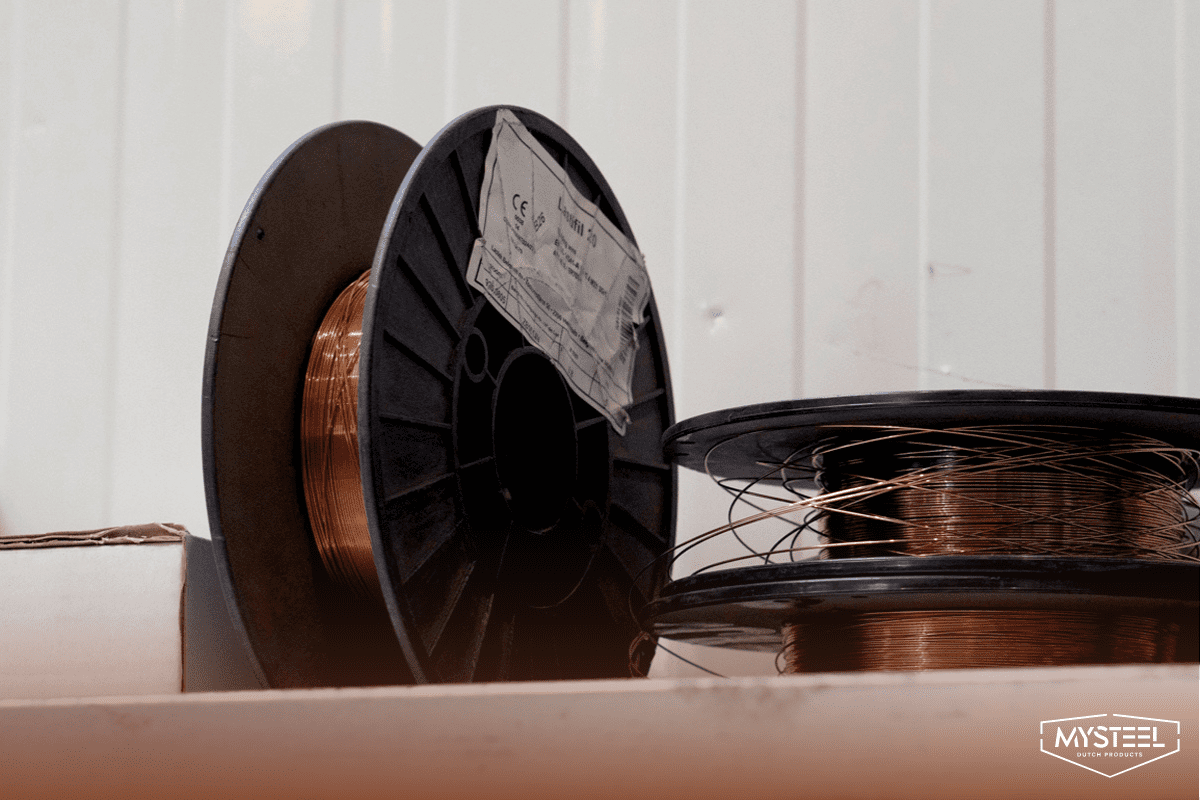

- Welding wire of corten steel or corten steel welding electrode: This ensures that the welding wires will also rust along with the material. They provide strong and durable welds.

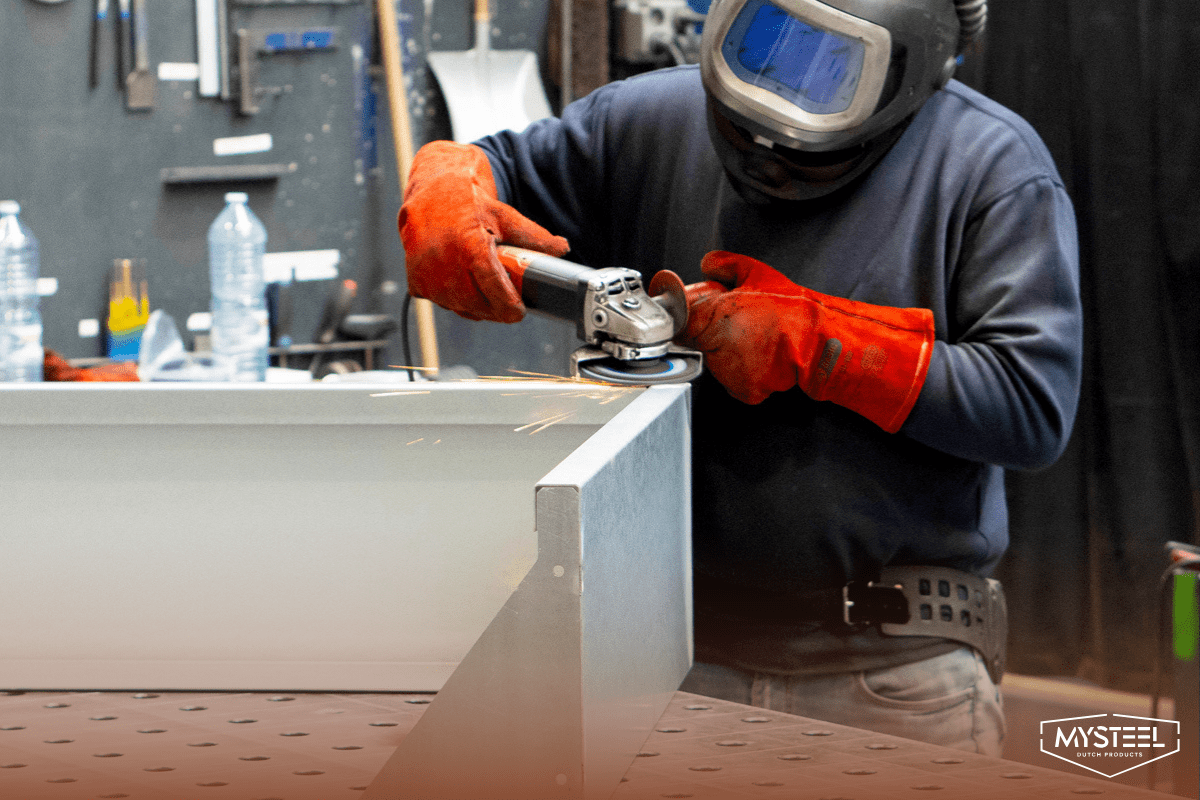

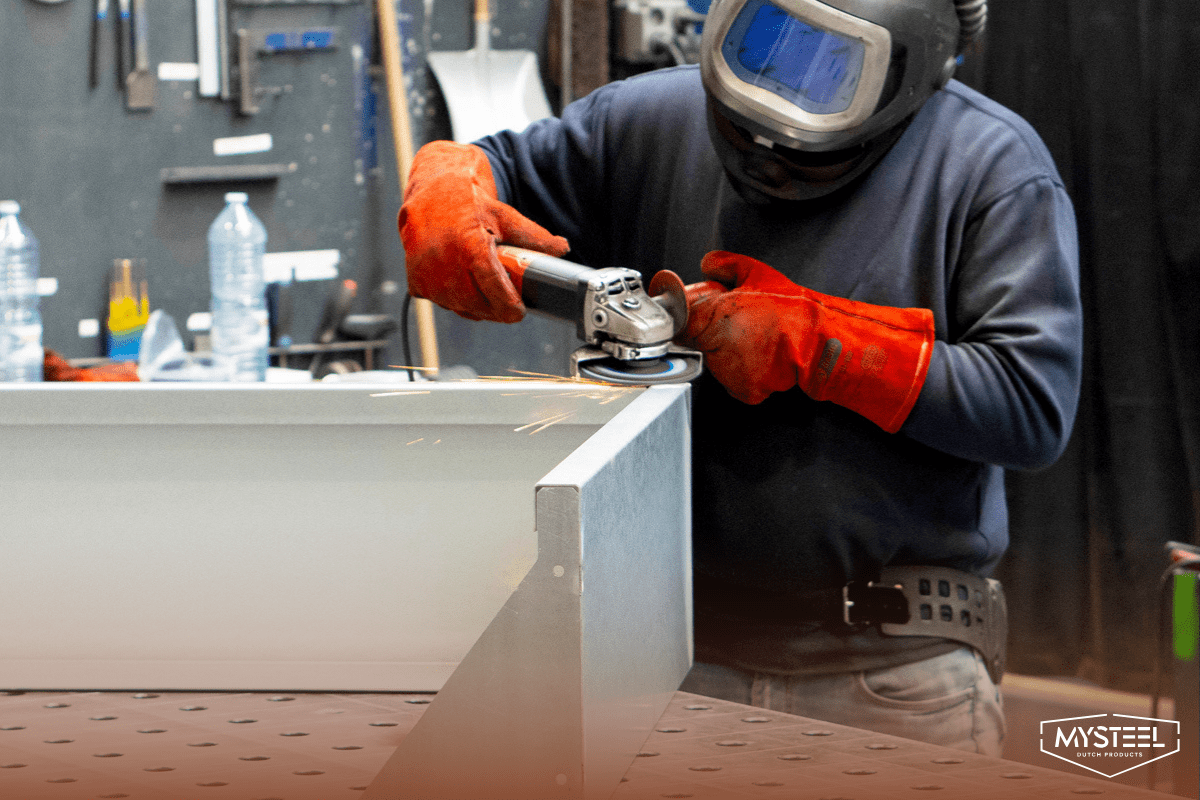

- Grinder: To smooth the entire piece after welding, you need a grinder. For a straight and tight result, you can use 3M Cubitron™. For curves, it is best to use a flap disc.

Step-by-step plan: How do you weld two pieces of corten steel together?

Corten steel is a versatile material that you can weld in different ways. You can weld corten steel with:

- Electrodes

- MIG/MAG (Metal Inert Gas/Metal Active Gas), also known as CO2

- TIG (Tungsten Inert Gas)

These different welding techniques each offer their own advantages and require specific skills and equipment. To choose the right welding technique, it is best to consider the requirements of the project and your own knowledge and experience.

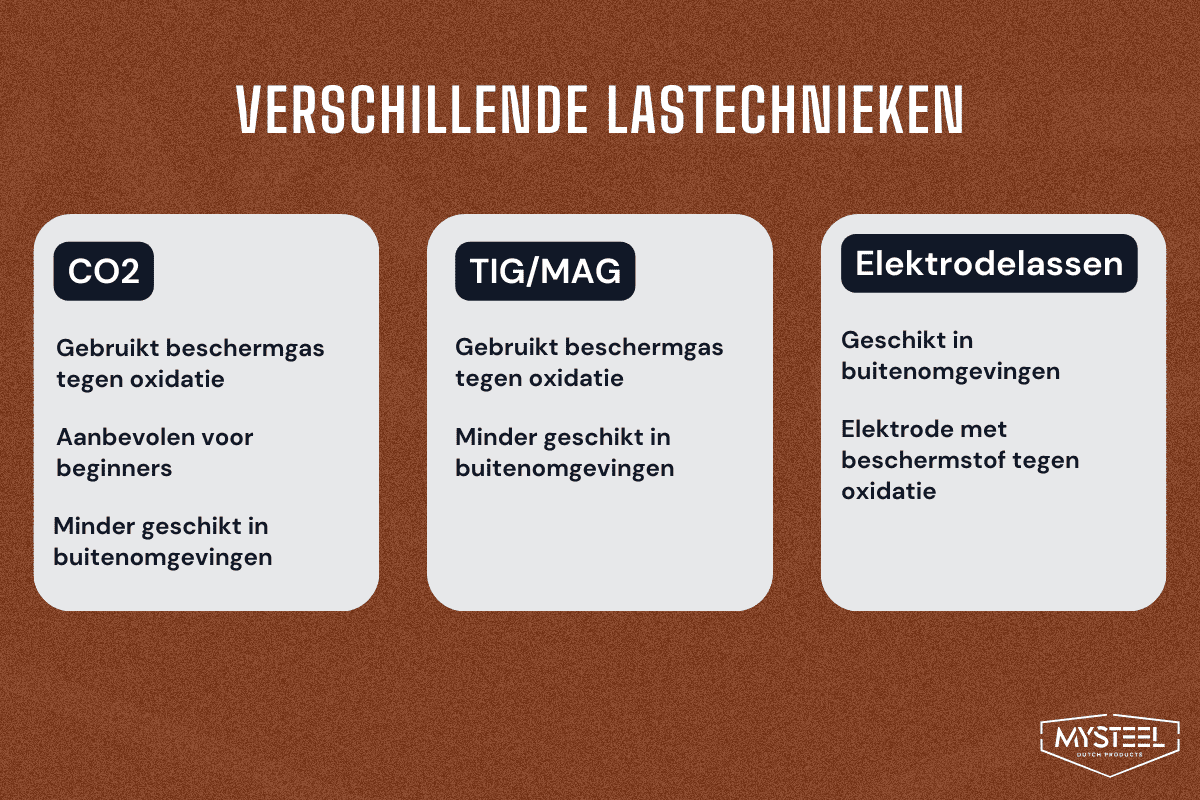

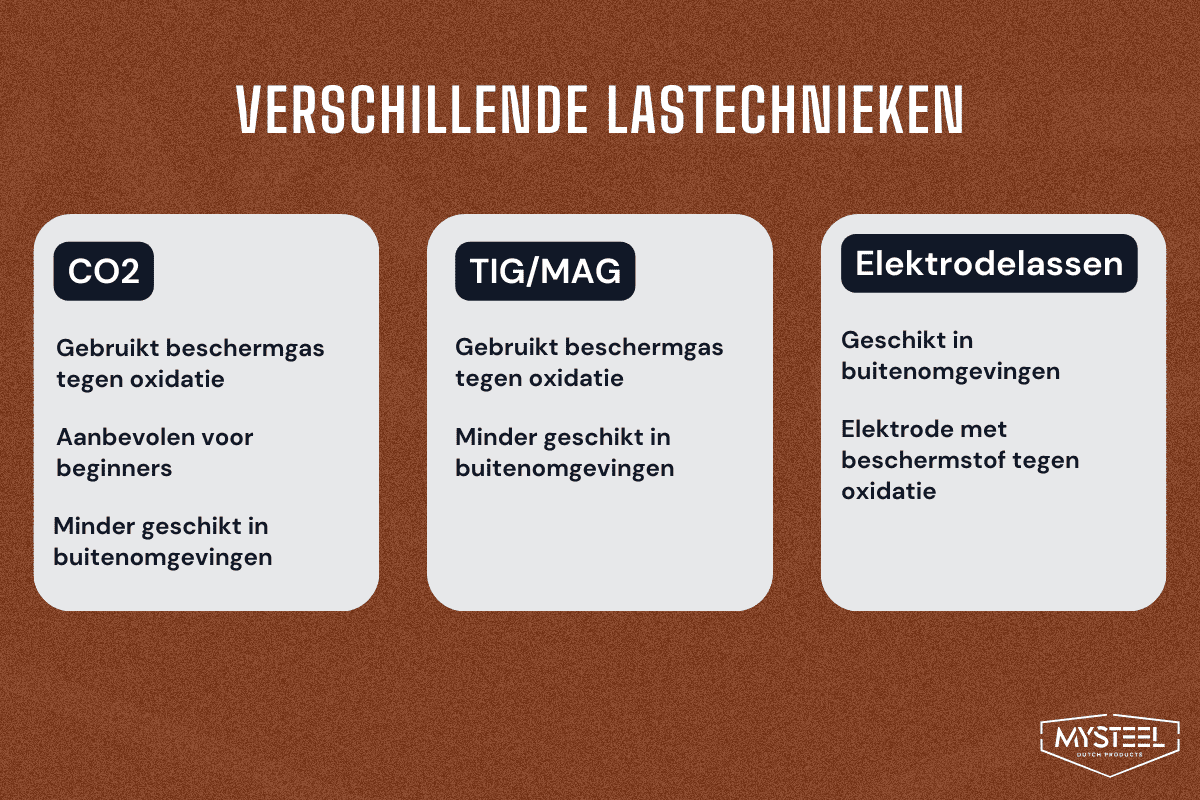

Different welding techniques

CO2 welding is the easiest way to weld and is often recommended for beginners, while TIG welding requires more experience.

During CO2 and TIG welding, protective gas is used to shield the molten pool from air. In outdoor environments, the gas can blow away.

With electrode welding, a protective substance is applied to the molten pool to protect it from air. Therefore, this welding technique is handy if you want to weld outdoors.

Below we explain step by step how you can successfully weld corten steel yourself. With this information, you are well prepared to make welding joints with corten steel.

Important

Please note that the warranty is void if you weld MySteel products yourself.

1. Clean the surface well

Before you start welding, you need to clean the surface well. The material does not need to be perfectly clean, but make sure to remove sand and other loose particles.

You can use a steel brush to go along the edges of the corten steel to ensure a nicer weld. The corten steel has a light scaling layer and a grease layer. While removing this scaling may have a small effect on the welding process, this effect is minimal and not necessary for welding.

Are you welding with a TIG machine?

Then it is important to first degrease the steel well. This prevents dirt from getting into the molten pool and causing holes in the weld joints.

2a. Use the right electrode and settings

To properly weld corten steel, it is important to use the right electrode. The most common electrode for corten steel is AWS-SMAW E71T1.

The welding settings also play a role in the success of the welding process:

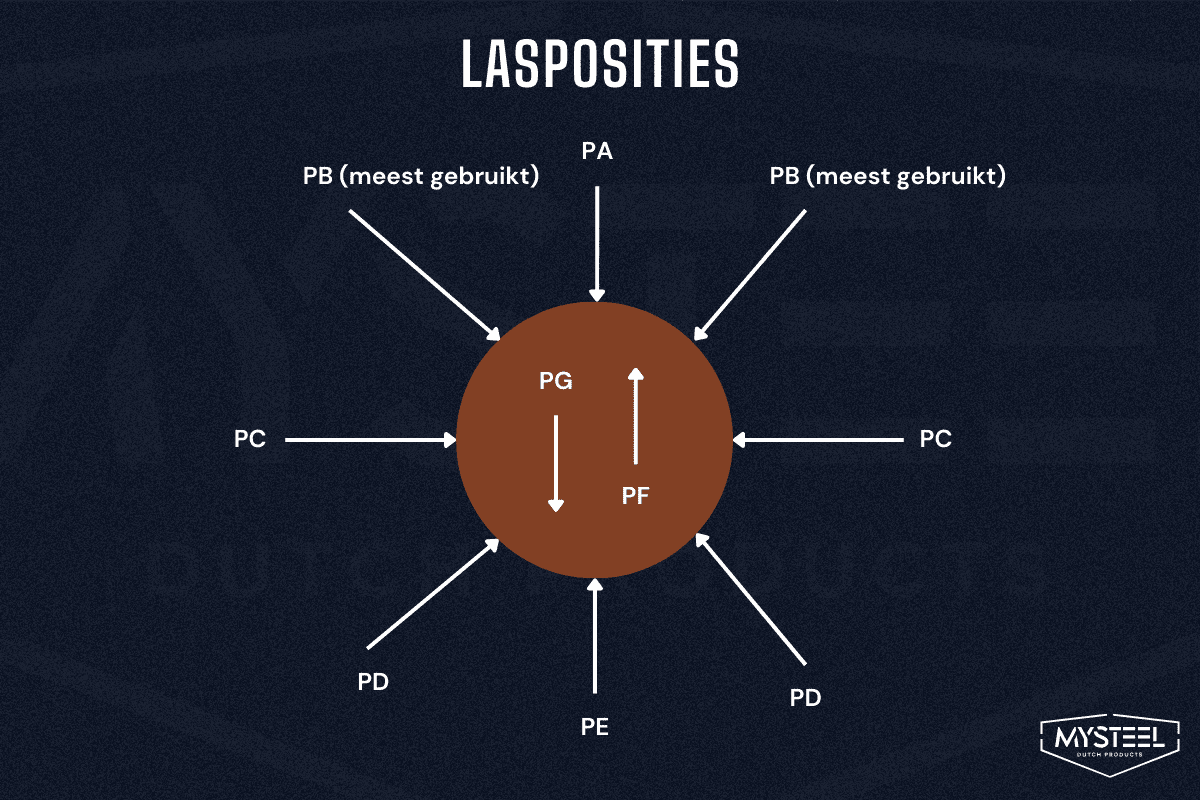

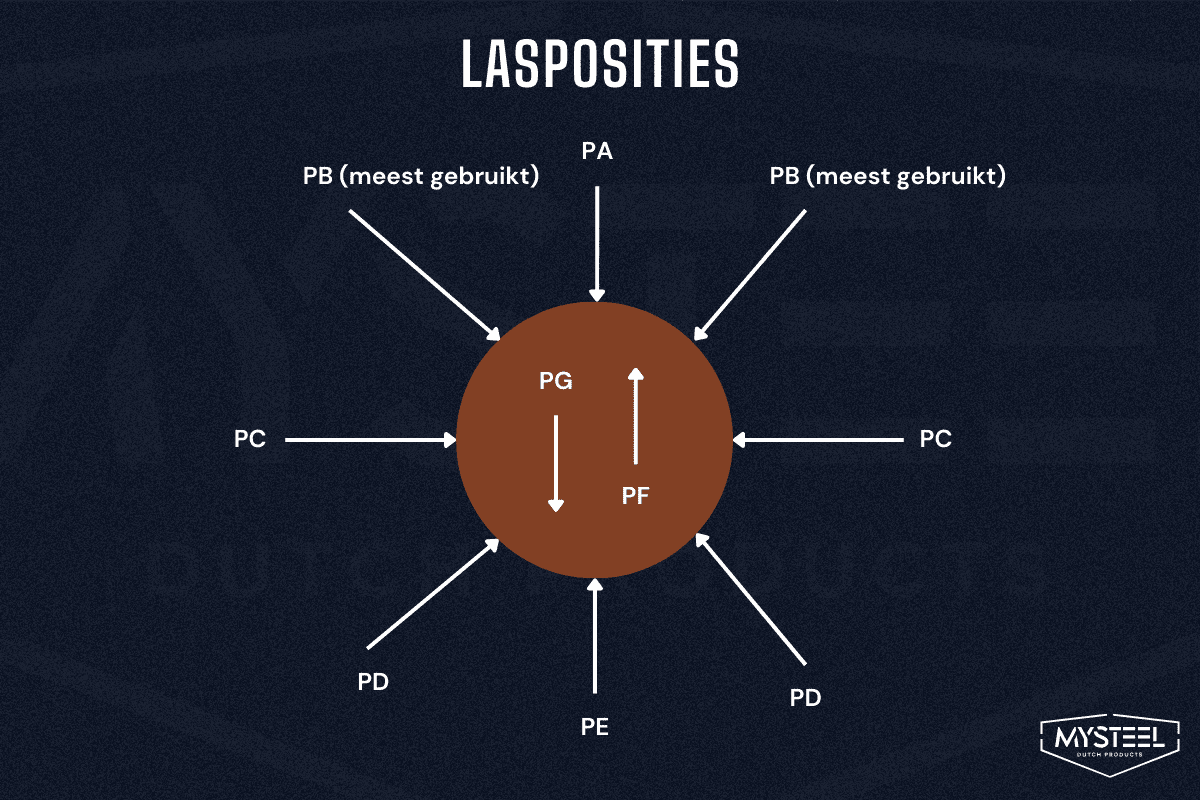

Welding position

First, you need to choose the right welding position. In the diagram below, you can see various possible positions. Each position has its own letter combination.

The easiest and most commonly used position is the PB position, also known as 'welding with the hand underneath'. Do you want to weld from top to bottom? Then PG is the most convenient position, but the root penetration is less than with PF. On the other hand, PF welding is often more challenging, as it can easily create a hole.

Welding speed and current

Additionally, welding speed and current are important. The welding speed depends on the settings of your welding machine. You need to set your device so that you achieve a nice bead without too much burn-through. Too much burn-through leads to unnecessary heat in the material and can even create holes.

Create test welds

Do you want to be sure you have the right settings? Then you can first create test welds on a piece of material of the same thickness. Pay attention to the width and height of the weld. If the weld is wide but low, your welding machine is set too high. If the weld is high but narrow, your welding machine is set too low.

Avoid cratering

With the right settings, you can also avoid cratering. This occurs when the heat is too high, causing the molten pool to pull the material inward and create a crater. This results in an unsatisfactory finish, as you cannot grind the surface flat. You can solve this by adding an extra weld and then grinding again.

At MySteel, we usually weld with a CO2 machine, but we also use TIG welding machines, depending on the project.

2b. Use the right welding wires/materials

The welding wires or materials you need depend on the type of welding process you are performing. Below we discuss the different options for TIG, MAG, and electrode welding.

TIG welding

For TIG welding of corten steel, you have various options for welding wires. If you weld without wire, the corten steel fuses together. Since you are joining the same material, it will not rust through later. However, keep in mind that if you weld without wire, there may be cratering. If you use a welding wire made of a different material, you run the risk of the weld seam rusting through over time.

With a 1.2 mm welding wire, you get tighter welds, while a 2.4 mm wire results in more rounded welds. Which wire diameter you choose depends on the gap you need to fill.

MAG welding

For MAG welding, the most commonly used wires are 0.8 mm, 1.0 mm, and 1.2 mm. If you are making lightweight constructions, a 1.0 mm wire is suitable. For larger constructions, you usually use a 1.2 mm wire.

With thinner materials, it is better to use a 0.8 mm wire. This is because you need more amperage to ignite a thicker wire, while high amperage is not necessary for thin materials. Therefore, a 0.8 mm wire is the best choice for thin materials. If you only have a thick wire for thin products, that is not a problem, but it is important to properly adjust your welding machine.

Electrode welding

In electrode welding, the thickness of the electrode depends on the material thickness and the gap you need to weld shut. To properly set the machine, it's best to create a few test welds first.

Modern electrode welding machines can often be plugged into a standard 220 V outlet. Just make sure to choose a circuit that is not overloaded with other devices, to prevent the power from tripping.

Welding outdoors with CO2

If you want to weld outdoors with a CO2 welding machine, you can use rutile filled wires. Since the wire is already filled, you do not need a separate protective gas.

3a. First, make tack welds

Before you start fully welding the materials, it is important to first make tack welds. Tack welds, also known as spot welds, are used to hold the parts you want to weld in place.

Welding two pieces together (straight and angle)

For connections where two pieces meet straight against each other, tack welds are sufficient. The goal is to securely hold the materials without fully welding them. Fully welding can distort the whole due to the heat. When welding angle joints, there is usually less chance of distortion, so you need to worry less about that.

Welding a square object

If you have multiple pieces, such as a square object, you should first tack everything before you start final welding. This ensures that everything remains stable and prevents parts from shifting during the welding.

3b. Weld small pieces with short breaks

During the welding process, it is wise to break the work into small sections and take regular short breaks. This allows you to better manage the heat output and prevents the material from warping. You will also have more control over the process, resulting in better weld quality.

4. Remove slag remnants

After electrode welding, slag remnants often remain on the material. It is important to remove these slag remnants to obtain a smooth and clean weld. You can do this with a special slag hammer, but you can also simply use a chisel or screwdriver.

With CO2 and TIG welding, there is no slag. So you can skip this step.

5. Let the corten steel cool down

Once you have finished welding, it is best to let the corten steel cool down before you do a check and any finishing work. This prevents you from burning yourself.

6. Sand the seams to prevent sharp edges

After welding, it is important to smooth the seams to prevent sharp edges and achieve a nice finish. A common way to do this is to grind down the weld. This makes your product look like a single unit.

Grinder

You can best do this with a grinder. For a nice flat surface, you can use 3M Cubitron™. If you do not have that, you can also use a flap disc, but that may sometimes cause a small bulging. For corners or curves, it is better to use a flap disc for a more accurate result.

Finishing with sandpaper

The grinding may cause light scratches, but these will become less visible over time due to the rusting process of corten steel. If you prefer an even better result, you can finish the whole with sandpaper of at least P120 or higher. You can also use Scotch-Brite to smooth out the last imperfections and achieve a perfect finish.

Rusting of the weld seams

The weld seams of corten steel will eventually rust along with the rest of the product. After you have polished it, the polished area will rust faster than the rest. This is due to the scaling layer, a layer that forms on corten steel during the production process and temporarily protects against rusting. When you grind the whole piece, you remove this scaling layer. Therefore, the material will rust faster.

It is not recommended to weld corten steel with regular welding wire. This can cause a problem. While corten steel itself develops a protective layer, this does not apply to the weld seams. As a result, they may rust through and eventually even break apart.

If you want to weld corten steel, it is therefore better to use a corten steel welding wire for a better and more durable result.

Suitable welding wires for corten steel

It is therefore important to choose the right welding wire. By using corten welding wire, you ensure that your projects are durable and of high quality.

How much you pay per kilogram depends on various factors:

- The diameter of the wire

- The brand

- The quantity of wire you buy from the store. Usually, larger quantities are more economical.

Protection and finishing

After you have welded something, it is important to properly protect and finish your product. This ensures that you have a durable and safe end product. What should you keep in mind?

After welding, weld spatter and points may remain on the weld, which can be sharp and dangerous. Therefore, it is best to remove these weld spatter and points if you want to keep the weld. If you grind down the weld, it will be smooth and thus safe.

Tips for finishing the weld seams

How can you best finish the weld seams? Follow these steps for a smooth result:

- Start by grinding down part of the weld, leaving a small piece.

- Repeat this along the entire length of the weld seam.

- Use long strokes to grind away the last bits of weld material. This ensures an evenly ground surface.

- Let the grinder do the work and do not press too hard. Too much pressure can cause dents in your product.

Practical applications and inspiration

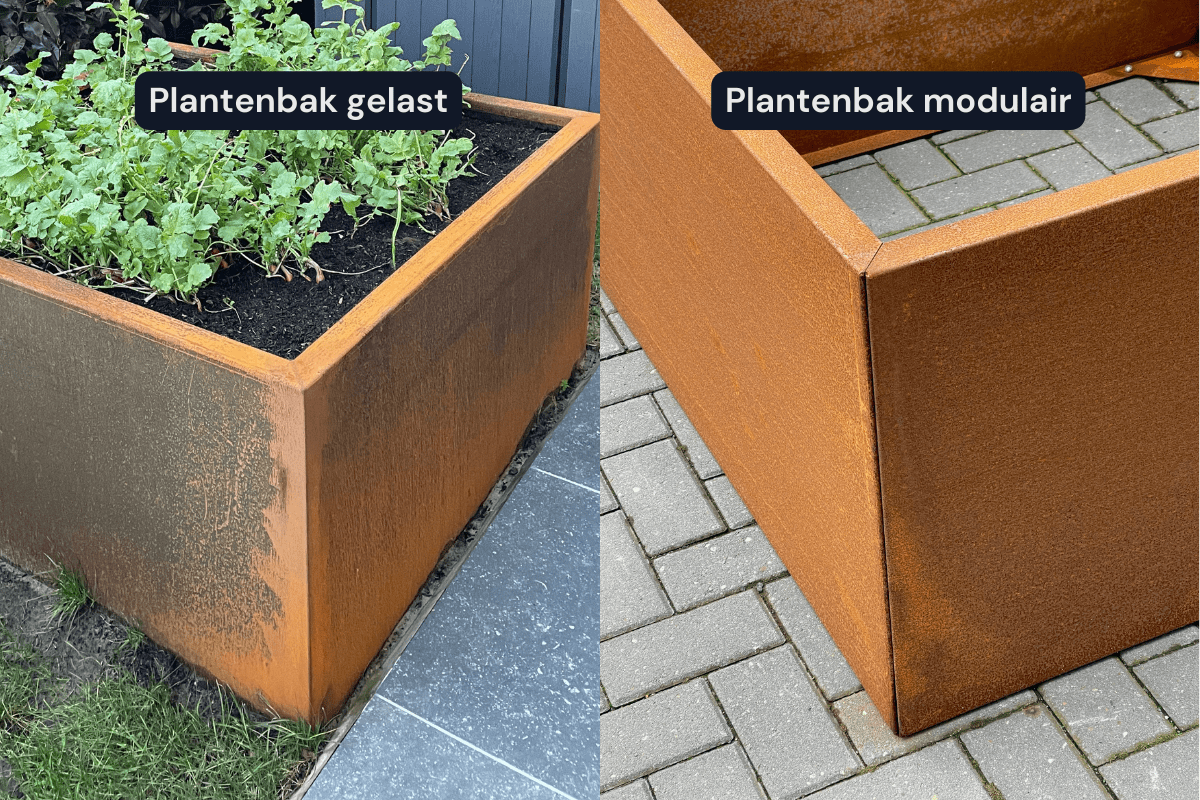

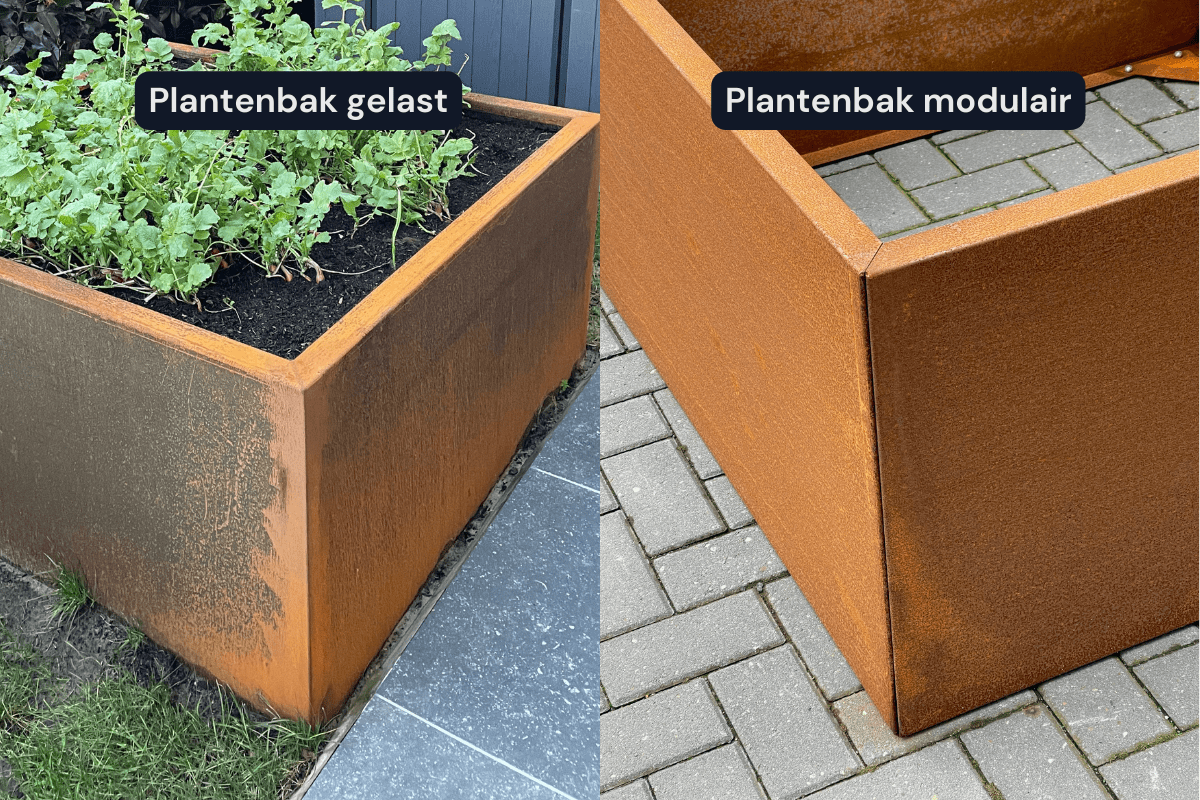

By welding corten steel, you can create unique products. At MySteel, in addition to our modular corten steel planters, you will also find various welded planters. These are not only durable but also give a unique appearance to your outdoor space.

But there are many more creative possibilities. You can also weld decorations, garden furniture, or fences that perfectly match your style and needs.

Conclusion

Welding corten steel requires good preparation, precise execution, and great attention to detail. With the right knowledge, tools, and techniques, you can create strong weld joints. By welding corten steel yourself, you can get creative and build unique and functional garden products.