The rusting process of corten steel explained

Corten steel, known for its unique rusty appearance, is very popular in the world of garden and landscape design. But how exactly does that characteristic rust layer develop on this type of steel? Discover everything about the fascinating rusting process of corten steel. From the first signs of oxidation to maintaining that beautiful look. Curious? Then read on!

Summary

- The rusting process of corten steel begins in the first 2 months, and the full process can take 1 to 2 years.

- Corten steel rusts fastest in humid and warm climates.

- Corten steel rusts less quickly when covered with grass, plants, or covers.

- The rusting process can be accelerated by using a rust accelerator.

- The use of varnish, paint, chemicals, or coatings is not recommended.

What does the rusting process of corten steel look like?

The rusting process of corten steel occurs due to a unique chemical reaction between the metals iron, copper, chromium, nickel, and phosphorus, and environmental factors such as moisture and oxygen.

This reaction, also known as oxidation, leads to a protective rust layer. This layer not only protects against further corrosion but also gives the material an attractive appearance due to its characteristic rust color. This natural process just needs some time.

How long does it take for corten steel to rust?

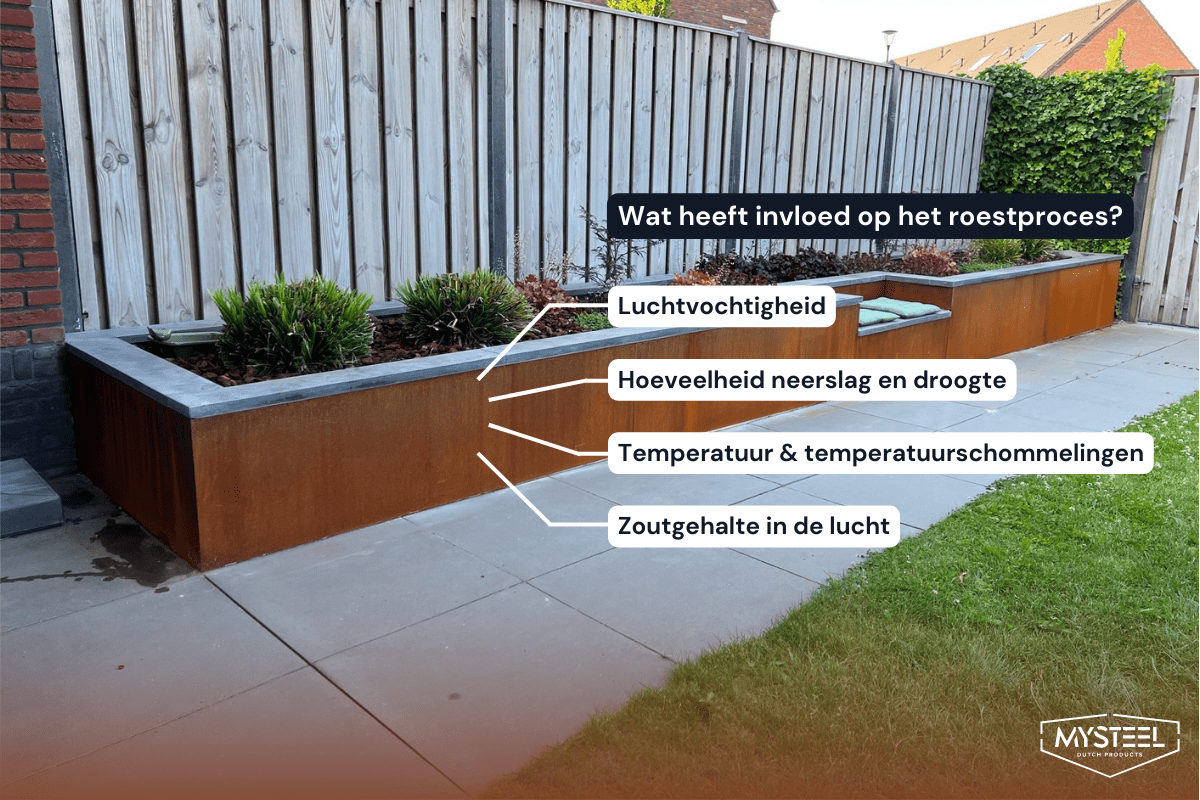

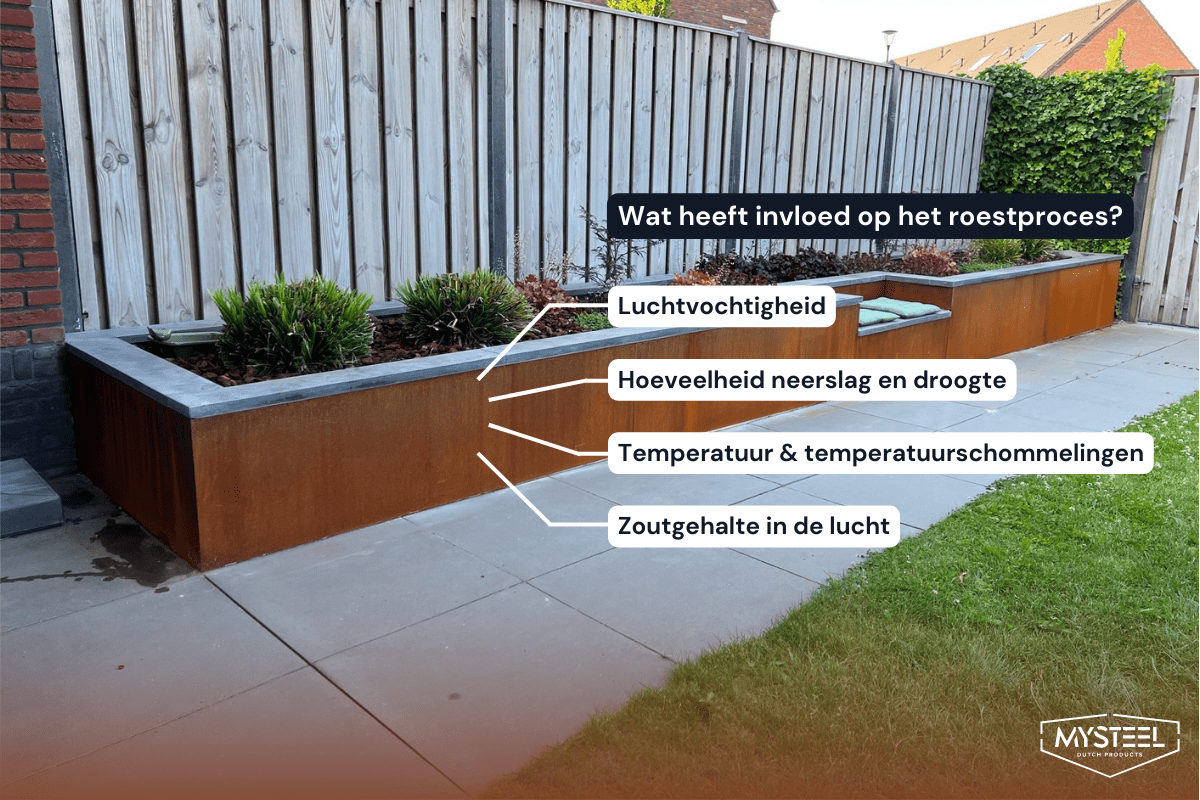

The first rust appears quickly, usually within a few days or weeks. This depends on the humidity and temperature of the environment. The full rusting process usually takes between 1 to 2 years. How quickly corten steel rusts depends on the following factors:

- Humidity and precipitation

- Temperature and temperature fluctuations

“The complete rusting process of corten steel can take between 1 to 2 years.”

The influence of climate

The rusting process of corten steel is influenced by various factors. Humidity and temperature play a significant role in this.

The rusting process works best in environments with a temperate climate where the humidity is not extremely high, but where there is enough moisture to initiate the rusting process and promote the development of the layer.

Temperature fluctuations also influence the rusting process. In the Netherlands, where humidity is high, for example, a rust layer forms more quickly than in southern France.

Role of humidity and precipitation

The degree of humidity and the amount of precipitation play an important role in the rusting process of corten steel. Under humid and rainy conditions, corten steel reacts with oxygen, resulting in a protective rust layer. Without moisture, such as in a dry climate, it may take longer for the rust layer to form.

Indoors

You can place a corten steel item indoors, but it is wise to place it outside for a year first, so it can rust properly. Once the rusting is complete and the material no longer transfers rust, you can use it indoors without worry.

Is it useful to spray corten steel with water?

It is beneficial to spray the corten steel planters with water in drier weather conditions. The spraying is purely intended to activate the rusting process. In a too dry environment, corten steel will not rust.

Tip

Water not only plays a role in activating the rusting process, but can also consciously serve an aesthetic function in the garden – for example, with a corten steel water table, which perfectly complements the natural appearance of this material.

Influence of temperature and temperature fluctuations

Rust formation on corten steel results from a chemical reaction on the surface. Variable temperatures, a minimum temperature of 10 °C, and humid, oxygen-rich conditions are necessary for this reaction. The warmer the steel, the quicker the reaction occurs.

Freezing cold

Freezing cold does not negatively affect the rusting process.

“Especially humidity and temperature play an important role in the rusting process of corten steel.”

Coastal areas

The conditions in coastal areas are different from those inland. The presence of salt in the air, humidity, and the impact of sea breeze accelerate the rusting process of corten steel. Salt is harmful to the steel, which results in a shorter lifespan of the corten steel. MySteel therefore recommends not using corten steel within a radius of 5 km from the coastline.

Very dry areas

In very dry areas, there is generally less moisture present. Corten steel still rusts here, but more slowly than in moister environments.

Tip

In a dry area? Spray the corten steel with water to initiate the rusting process.

How to make corten steel rust faster?

We recommend letting the rusting process take its natural course. However, if you want faster results, you can try other methods to speed up the rusting process of corten steel.

We will inform you below about the steps and precautions for each method.

Rust accelerator

If you are looking for a ready-made solution, our rust accelerator pro+ is for you. Thanks to the new PRO+ formula, the first rust formation often occurs within just one day. First, degrease the corten steel, spray the rust accelerator liquid on, roll it out with a paint roller to avoid spots, and repeat this to reactivate the accelerated rusting process. Note: avoid contact with clothing, tiles, and sensitive surfaces to prevent staining.

Have you seen our combi deal? This way, you have the right materials at home to degrease your product and then treat it so that the oxidation process can start!

Tip

Do not wipe the rust accelerator over the surface. This can create streaks or smudges that can be visible for a long time.

Why is your corten steel product rusting so slowly?

Rusting proceeds slowly and gradually because iron reacts with oxygen and water to form iron oxide (the orange-brown rust layer) on the steel.

Unfavorable weather

In very dry conditions, there might not be enough moisture available for the protective rust layer to form. In such conditions, the rusting process can slow down or possibly stop. It certainly makes sense to spray the material with water from time to time.

Close to coastal areas

The presence of salt in the sea air prevents the stabilization of the rust. Therefore, we advise against letting corten steel rust within a radius of 5 km of the coast.

What should you not do if you want to make corten steel rust quickly?

Do you want to make corten steel rust quickly? Avoid the following points:

Do not use coatings or chemical cleaners

Do not use protective coatings and chemical cleaners.

Do not cover your products

Ensure that the corten steel always remains in contact with air and water. Do not cover your corten steel planters with covers and avoid having parts of the corten steel border covered with, for example, sand or dense plant growth.

Do not use paint or varnish

Avoid using paint, varnish, or other types of finishes on corten steel. These substances prevent the steel from coming into contact with oxygen and water, which slows down the rusting process.

Varnish can be used to ultimately slow down the rusting process. Read more about this in the section “Are there special coatings for corten steel to slow down rust formation?”

Do not use chemicals

Do not clean corten steel with chemicals that can remove the oxidation layer. This will slow down the rusting process.

Can corten steel rust completely through?

In most circumstances, the rust layer of corten steel will stabilize after a certain period of exposure to the elements. The layer formed will protect the steel against further corrosion. In some unfavorable environments, such as coastal areas with high salt in the air, it is possible that the material may rust through more than would normally be the case.

Constant exposure to water

What happens if corten steel is constantly wet? If corten steel remains wet for too long, it cannot dry properly. This increases the likelihood of rusting through. Therefore, it is less suitable to place it by a pond, where the moisture level is high and can remain moist for an extended period.

Corten steel needs time before it gets a nice color

The rusting of corten steel is a completely natural process and proceeds slowly. Even with a rust accelerator, it takes some time to develop the characteristic, robust color. Once you have achieved that beautiful color, it is important to maintain your corten steel well. This way, you can enjoy it for a long time.

Conclusion

We hope this article has given you insight into the rusting process of corten steel. If you have more questions or a specific product inquiry after reading, feel free to contact the customer service of MySteel. We offer a wide range of corten steel products that give your garden a distinctive appearance. Feel free to explore our selection and get inspired.