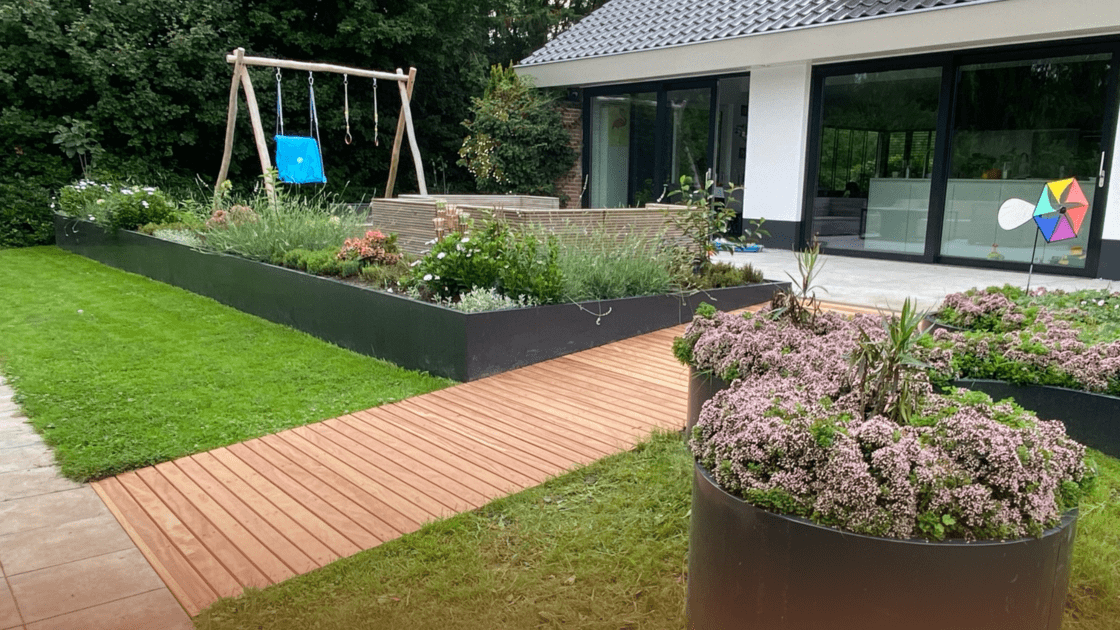

Working with corten steel like a pro: grinding, drilling, sawing, and other techniques explained

Corten steel is a versatile material that you can process in various ways. Grinding, drilling, sawing, or powder coating: there are many possibilities with corten steel.

However, before you start working with corten steel, it is important to be well prepared. For each processing method, you need special knowledge and the right tools to achieve good results. In this blog, we will explain step by step how to work with corten steel. This way, you can get started like a true professional.

Note

Please be aware that the warranty on MySteel products is void if you process them yourself.

Summary

- Corten steel can be processed in various ways: grinding, drilling, sawing, powder coating, or laser cutting.

- If you want to drill in corten steel, you need to use the right drill and technique to safely create holes.

- The quickest way to grind corten steel is with an angle grinder, but for smaller parts, you can also use a metal saw.

- Powder coating provides long-lasting protection and a beautiful finish.

- Laser cutting is a modern technique that allows you to cut corten steel accurately and quickly.

How can you cut through corten steel?

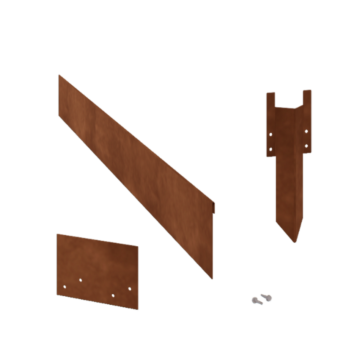

The best tool to cautiously cut through corten steel is a angle grinder. You can also use an angle grinder to bend corten steel border edges. You do this by not cutting all the way through the corten steel, but only scoring it. This way, you can bend the material, which is handy if you want to create round or angular shapes in your design.

Reading tip

Want to know how you can place a border edge yourself? Read our blog on placing a corten steel border edge.

How can you drill into corten steel?

You can drill well into corten steel if you use the right technique and tools. The equipment you need depends on the size of the holes you want to create.

Holes up to 12 mm

For holes up to 12 mm, you can use a regular cordless drill and a standard metal drill bit. If you want to drill a hole larger than 8 mm, it is smart to first pre-drill with a bit that is half the final diameter. So, if you want to make a 9 mm hole, start with a 4.5 mm bit.

Holes larger than 12 mm

Do you want to make a larger hole? Then you can use a hole saw that is suitable for metal. Start by pre-drilling with a 5 mm drill bit. After that, you can use the hole saw to make the hole as large as you want.

In both cases, it is important to use cutting oil. This helps prevent the drill from overheating and ensures that the drill lasts longer.

“It is advisable to use protective gear, such as safety glasses, hearing protection, and safety shoes when working with metal.”

Procedure

To ensure that the hole is in the right place, first mark the location by crossing two lines. Use a center punch, awl, or cross-point screwdriver to create a center point at this intersection. This ensures that the drill bit does not slip and has a stable starting point.

You can set the cordless drill to a high speed, but be careful during the last part of the drilling. Here, the drill bit may catch, causing the cordless drill to spin instead of the bit.

Safety and finishing

Remember to wear safety glasses to protect your eyes. It is also wise to use other protective gear, such as hearing protection and safety shoes when working with metal. If you wear gloves while drilling, be extra cautious and never touch the rotating drill.

After drilling, it is important to smooth the edges of the holes with a countersink, file, or sandpaper, so there are no sharp edges left.

Can you also saw corten steel?

Yes, you can saw corten steel, but the best way to ‘cut off’ corten steel is by grinding it with an angle grinder. For smaller objects like shafts or tubes, you can also use a metal saw. This is not feasible for wider materials. Moreover, sawing with a metal saw takes much longer than grinding with an angle grinder.

If you use a metal saw, it is important that you apply force on the material during the pushing motion. The pulling motion does not produce a sawing effect and can dull the saw. After sawing or grinding, as with drilling, it is important to smooth the edges with sandpaper or a file, as these edges can be very sharp.

Important

Please note that the warranty is void if you process MySteel products yourself.

How can you powder coat corten steel?

Powder coating is an electrostatic process where powder is applied to metal with a special spray gun. The metal is then heated in an oven, causing the powder to melt. It then becomes viscous and ultimately hardens, forming a strong and beautiful layer on the metal.

Preserving rust color

If you want to preserve the natural rust color of corten steel after powder coating, you must let the steel rust first. After that, you can use a clear varnish to protect the rust color.

Powder coating corten steel in another color

Would you prefer a different color? Then you don’t need to let the corten steel rust before you start powder coating.

How can you cut corten steel with a laser?

To cut corten steel with a laser, you use a laser cutting machine that creates a concentrated beam of light. This beam is less than 1 mm wide and forms a powerful ray with great intensity. This makes it possible to cut materials accurately.

The laser melts the corten steel precisely where the beam hits. This is a modern way of cutting, which is more accurate and faster than traditional methods such as a gas torch or plasma cutter.

To achieve the right melting, nitrogen or oxygen is added during laser cutting. These gases ensure that there are no edges or bubbles forming on the underside of the steel. This results in a smooth and neat finish.

With a laser, you can cut corten steel up to a thickness of about 20 mm.

Conclusion

Working with corten steel requires attention and good tools, but with the right techniques, you can work professionally. Whether you want to grind, drill, saw, powder coat, or laser cut, each processing method has its own considerations. Now that you know the key techniques, you can confidently start your corten steel projects. Start today and turn your ideas into beautiful creations!